Notifications

5 minutes, 52 seconds

-128 Views 0 Comments 0 Likes 0 Reviews

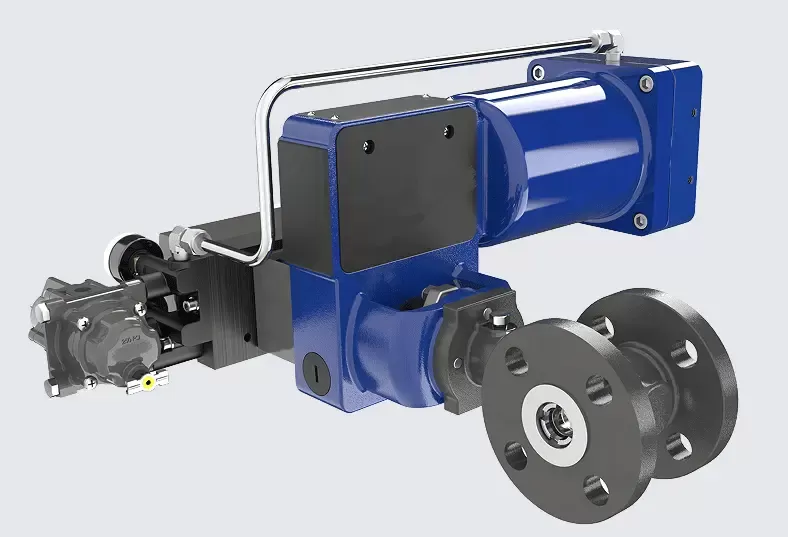

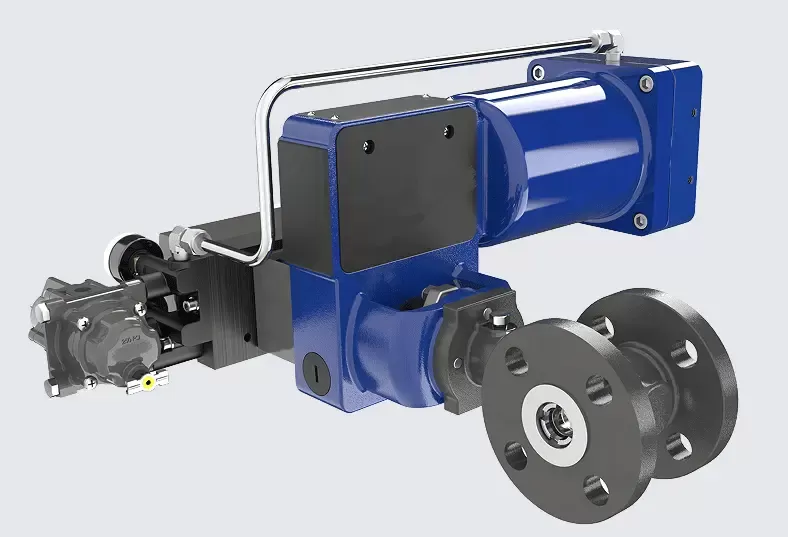

China Control valves are vital components in industrial fluid systems, enabling precise regulation of flow, pressure, and direction. Among the various types, eccentric plug control valves stand out due to their unique design and superior ability to handle challenging media such as slurries, viscous liquids, and abrasive fluids.

This article explores the working principle, key features, applications, and performance advantages of eccentric plug control valves—offering a comprehensive guide to their role in modern industrial processes.

An eccentric plug control valve is a quarter-turn rotary valve specifically engineered for precise flow regulation. Unlike conventional plug valves, it uses an off-center (eccentric) plug, which minimizes friction and wear by lifting away from the seat during operation rather than sliding across it.

Eccentric Plug: Offset design reduces seat contact during rotation, lowering friction and enhancing service life.

Robust Construction: Often built with stainless steel or hardened alloys for high durability.

Tight Shutoff: Achieves a secure seal even under high pressure, minimizing leakage.

Self-Cleaning Action: Rotating motion prevents debris accumulation on sealing surfaces.

These features make eccentric plug valves ideal for demanding environments like oil and gas, chemical processing, power generation, and water treatment.

The operation of an eccentric plug control valve revolves around a simple yet highly efficient mechanism:

The eccentric plug presses against the seat to form a tight seal.

The off-center design provides uniform sealing force and leak prevention.

The plug rotates 90° away from the seat.

Eccentric movement disengages the plug early, reducing friction and wear.

Partial rotation allows for precise modulation of flow.

Straight-through path minimizes turbulence and pressure drop.

The plug’s motion dislodges particles, preventing clogging.

Materials are selected for high abrasion resistance.

| Feature | Description |

|---|---|

| Tight Shutoff | Hard-seal (ANSI Class IV) or soft-seal (Class VI) for zero-leakage performance |

| Low Operating Torque | Offset plug minimizes friction |

| Self-Cleaning Action | Ideal for slurries and high-solid-content media |

| Extended Seat Life | Erosion-resistant design ensures longevity |

| Split Spool Design | Enables custom material combinations |

| One-Piece Stem | Ensures precise plug alignment |

| Anti-Fly-Out Stem Shoulder | Enhances safety by preventing stem ejection |

| Easy Maintenance | Simplified disassembly for fast servicing |

Flow control of crude, refined products, and natural gas

Resistant to high pressure and corrosive environments

Handles acids, alkalis, and corrosive slurries

Corrosion-resistant materials ensure reliability

Regulates boiler feedwater, steam, and cooling fluids

Withstands high temperatures and pressures

Controls sludge, slurry, and treated water

Self-cleaning design resists clogging

| Advantage | Benefit |

|---|---|

| Superior Flow Capacity | Straight-through flow minimizes pressure loss |

| Enhanced Durability | Hardened plug and seat resist erosion and abrasion |

| Reduced Maintenance | Self-cleaning design limits buildup and wear |

| Improved Safety | Anti-ejection stem ensures integrity under pressure |

| High Control Accuracy | Wide adjustable range supports precise modulation |

Selecting the right valve involves evaluating multiple factors to align with your system’s specific requirements:

Material Compatibility

Use stainless steel or alloys for corrosive media.

Apply hardened coatings for abrasive slurries.

Pressure & Temperature Ratings

Confirm the valve’s pressure class and temperature range.

Valve Size & Flow Capacity

Match pipeline size (DN/NPS) and check the valve's Cv value for performance.

Actuation Method

Choose manual for basic applications.

Opt for pneumatic, electric, or hydraulic actuation for automation or high-cycle use.

Sealing & Leakage Performance

Soft-seated for bubble-tight shutoff.

Metal-seated for extreme conditions.

Ease of Maintenance

Prioritize valves with tool-free access or quick-disconnect features.

Eccentric plug control valves provide robust, precise, and low-maintenance solutions for fluid control in tough industrial environments. Their unique design reduces wear, enhances sealing, and prolongs service life—making them a smart investment for industries such as oil & gas, chemical, power, and water treatment.

By selecting the right valve for your application, you ensure:

Reduced downtime

Enhanced flow efficiency

Long-term cost savings

Whether you're an engineer, plant operator, or procurement specialist, understanding the benefits of eccentric plug valves can help optimize your system’s performance and reliability.Know more about Google SEO Directory