Notifications

6 minutes, 20 seconds

-13 Views 0 Comments 0 Likes 0 Reviews

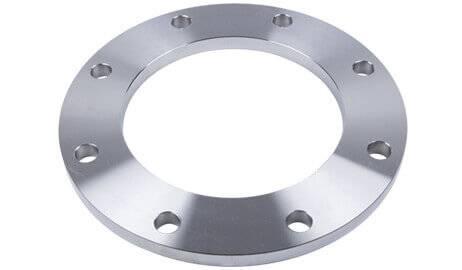

Flanges are essential components in piping systems, providing a reliable means of connecting pipes, valves, and other equipment. Among the various materials used in flange manufacturing, stainless steel (SS) 316Ti flanges stand out due to their remarkable performance in challenging environments.

This blog explores the unique properties, advantages, and common applications of SS 316Ti flanges, helping you understand why they are an excellent choice for industrial use.

What Are SS 316Ti Flanges?

SS 316Ti flanges are made from stainless steel alloy 316Ti, a titanium-stabilized version of the 316-grade stainless steel. The titanium addition enhances the material's resistance to high temperatures and prevents the formation of carbide precipitates during welding. This makes SS 316Ti an ideal material for flanges used in demanding applications.

Key Features of SS 316Ti Flanges

Titanium Stabilization

Titanium addition provides superior resistance to intergranular corrosion, especially in environments with elevated temperatures.

High-Temperature Resistance

SS 316Ti flanges can withstand temperatures up to 600°C, making them suitable for heat-intensive applications.

Corrosion Resistance

The alloy offers exceptional resistance to pitting, crevice corrosion, and general corrosion, especially in chloride-rich environments.

Durability and Strength

These flanges are known for their robust mechanical properties, ensuring long service life and reliability.

Ease of Fabrication

SS 316Ti flanges are easy to fabricate, weld, and machine, making them versatile for various applications.

Benefits of Using SS 316Ti Flanges

Long-Term Performance

The titanium stabilization minimizes carbide precipitation, ensuring reliable performance even under harsh conditions.

Low Maintenance

Their corrosion resistance reduces the need for frequent maintenance, saving time and cost.

Enhanced Safety

The superior strength and heat resistance make these flanges ideal for critical applications where safety is paramount.

Cost-Effectiveness

Though the initial investment might be higher, their durability and low maintenance needs make them a cost-effective solution in the long run.

Types of SS 316Ti Flanges

SS 316Ti flanges are available in various types to cater to different industrial needs.

Weld Neck Flanges

These are ideal for high-pressure applications and provide a seamless connection between pipes.

Slip-On Flanges

Known for their ease of installation, these flanges are suitable for low-pressure applications.

Socket Weld Flanges

Commonly used in small pipe diameters, these flanges offer a secure and leak-proof connection.

Blind Flanges

Used to seal the end of a piping system, blind flanges are essential for maintenance and inspection.

Threaded Flanges

These flanges are perfect for applications where welding is not feasible.

Lap Joint Flanges

These flanges work with a stub end and are commonly used in systems requiring frequent dismantling.

Applications of SS 316Ti Flanges

SS 316Ti flanges are widely used across industries due to their superior performance in challenging conditions.

Chemical Processing

Their resistance to corrosive chemicals makes them a popular choice in the chemical industry.

Oil and Gas

SS 316Ti flanges are used in pipelines, refineries, and offshore platforms due to their high strength and corrosion resistance.

Power Generation

These flanges play a vital role in heat exchangers and boilers in power plants.

Pharmaceutical Industry

The hygienic and non-reactive properties of SS 316Ti make them suitable for pharmaceutical production.

Food and Beverage Industry

Their corrosion resistance and ease of cleaning ensure compliance with food safety standards.

Marine Applications

The ability to withstand saltwater environments makes SS 316Ti flanges ideal for shipbuilding and marine infrastructure.

Why Choose SS 316Ti Flanges Over Other Materials?

Superior Performance

Compared to standard stainless steel flanges, SS 316Ti flanges offer enhanced resistance to high temperatures and corrosion.

Longevity

The durability of SS 316Ti flanges reduces the need for frequent replacements, making them a reliable option.

Versatility

Their compatibility with various pipe systems and media makes them a versatile choice for different industries.

Maintenance Tips for SS 316Ti Flanges

To ensure the longevity and optimal performance of SS 316Ti flanges, follow these maintenance tips:

Regular Inspection

Check for signs of wear, corrosion, or damage to identify potential issues early.

Proper Cleaning

Use mild cleaning agents to remove dirt, grease, and contaminants without damaging the surface.

Preventive Measures

Apply protective coatings or use gaskets to minimize exposure to corrosive elements.

Secure Installation

Ensure proper tightening and alignment during installation to prevent leaks or failures.

How to Select the Right SS 316Ti Flange?

Application Requirements

Consider the operating conditions, including pressure, temperature, and type of media.

Size and Dimensions

Choose the appropriate size and dimensions as per industry standards like ANSI, ASME, or DIN.

Flange Type

Select the flange type that best suits your piping system and operational needs.

Material Certification

Ensure the flanges meet industry certifications and standards for quality assurance.

Conclusion

SS 316Ti flanges are a reliable and durable solution for industries requiring high-performance flanges. Their resistance to heat, corrosion, and mechanical stress makes them a preferred choice for demanding applications. Whether it’s chemical processing, marine infrastructure, or power generation, SS 316Ti flanges deliver unparalleled performance and longevity.