Notifications

12 minutes, 22 seconds

-199 Views 0 Comments 0 Likes 0 Reviews

The Emergence of Smart Factories: Transforming the Manufacturing Environment

One of the most fascinating trends in manufacturing today is the Smart Factory Market. The idea of a "smart factory" has become revolutionary as companies rely more and more on technology to boost output, cut waste, and guarantee product quality. Using high-tech equipment is only one aspect of this shift; another is building data-driven, networked workplaces where workers, machines, and processes can communicate in real time. However, what does this actually mean for customers, companies, and manufacturing's future? Let's get started!

The Smart Factory Market Size was valued at USD 289.55 Billion in 2022 and is projected to reach USD 842.45 Billion by 2028, growing at a CAGR of 12.55 % over the forecast period.

Request Sample Copy:https://wemarketresearch.com/reports/request-free-sample-pdf/smart-factory-market/594

Company Analysis

An in-depth assessment of key players in the Smart Factory market, including their market positioning, strategies, product offerings, and competitive landscape.

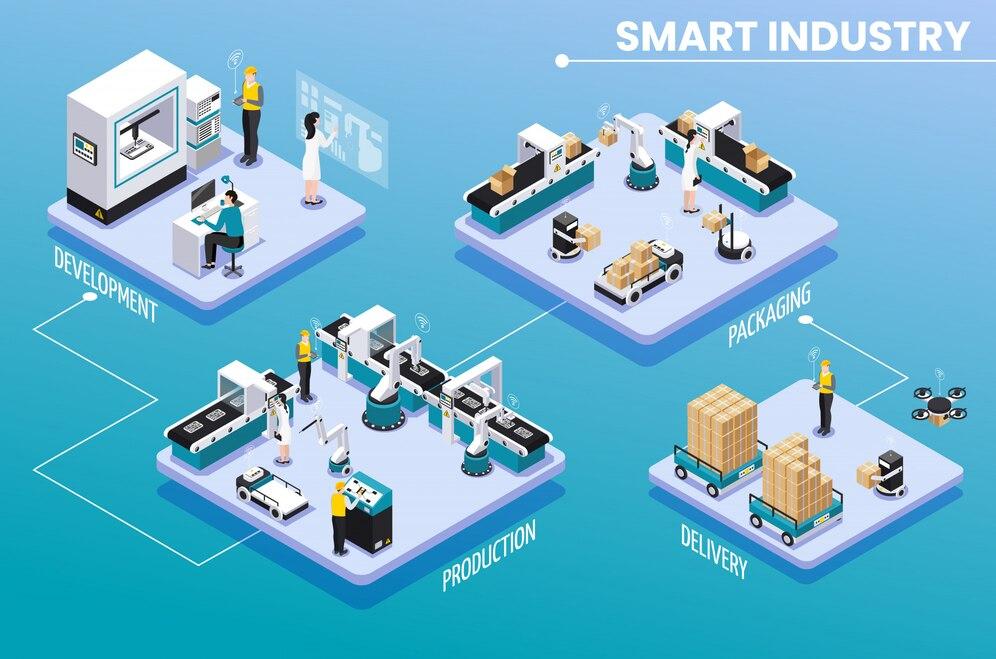

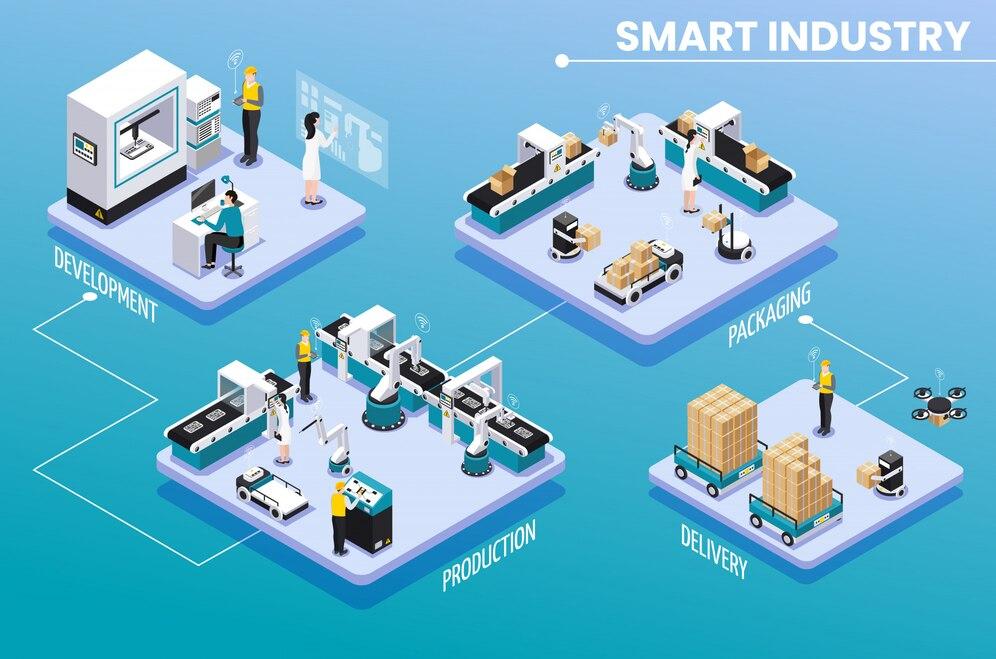

A Smart Factory: What Is It?

A "smart factory" is a highly automated and networked manufacturing facility that monitors and optimizes manufacturing processes using technologies such as artificial intelligence (AI), robotics, machine learning, IoT (Internet of Things), and big data analytics. Put simply, it's a factory that is more intelligent, effective, and flexible than it has ever been.

The days of manufacturing using either traditional machinery or human labor are long gone. These days, networked technologies in smart factories automate procedures, anticipate maintenance requirements, and enable real-time decision-making, revolutionizing the production and distribution of commodities.

Why is the market for smart factories expanding?

Increased Efficiency and Productivity: The primary driver behind the rise of smart factories is their ability to streamline manufacturing processes. Sensors embedded in machines, equipment, and even in the factory environment collect real-time data, which can be used to improve operational efficiency. Automation and predictive analytics can help minimize downtime, optimize energy consumption, and ensure that production runs smoothly.

Cost Savings: While the initial investment in smart factory technologies can be significant, the long-term benefits are clear. By reducing waste, improving quality control, and minimizing errors, smart factories help manufacturers cut down on unnecessary costs. Moreover, predictive maintenance can prevent costly breakdowns, further enhancing cost efficiency.

Customization and Flexibility: Today’s consumers want personalized products, and smart factories are stepping up to meet this demand. Advanced manufacturing systems can quickly adapt to changing consumer preferences or market trends, allowing for on-demand production and smaller batch sizes. This flexibility also means that smart factories can respond faster to disruptions, whether caused by supply chain issues or sudden shifts in demand.

Sustainability and Resource Management: As industries continue to focus on sustainability, smart factories are a major ally in reducing the environmental impact of manufacturing. With the use of sensors and real-time data, factories can reduce energy consumption, optimize resource usage, and minimize waste. By making processes more efficient, smart factories help reduce the carbon footprint of manufacturing operations.

Market Segmentation:

Based on Components, the market is segregated into

• Software

• Hardware

• Service

Based on Connectivity, the market is categorized into

• Wired connectivity

• Wireless connectivity

Based on Industry Vertical, the market is divided into

• Electronics and semiconductor

• Aerospace and defense

• Automotive

• Oil and gas

• Chemicals

• Healthcare and pharmaceuticals

• Others.

Key Players:

ABB, Siemens, General Electric, Rockwell Automation, Inc., Schneider Electric, Honeywell International Inc., Emerson Electric, Fanuc, and others.

Request Sample Copy:https://wemarketresearch.com/reports/request-free-sample-pdf/smart-factory-market/594

Access Report:https://wemarketresearch.com/reports/smart-factory-market/594

FAQ:

What is the market size of Smart Factory Market?

Who are the key vendors in the Smart Factory Market?

What is the key driver of Smart Factory Market?

What is the key market trend for Smart Factory Market?

Which region accounted for the largest share in Smart Factory Market?

What is the market size of Smart Factory Market?

Who are the key vendors in the Smart Factory Market?

What is the key driver of Smart Factory Market?

What is the key market trend for Smart Factory Market?

Which region accounted for the largest share in Smart Factory Market?

What is the global market size of Smart Factory Market?

Who are the key vendors in the Smart Factory Market?

What is the key driver of Smart Factory Market?

What is the key market trend for Smart Factory Market?

Which region accounted for the largest share in Smart Factory Market?

Explore Updated Reports:

Enterprise Imaging Solutions Market

AI-Enabled Medical Imaging Solutions Market

Key Technologies Driving the Smart Factory Market:

The success of smart factories relies heavily on the integration of various cutting-edge technologies. Some of the most important technologies driving the market include:

Internet of Things (IoT): IoT enables machines, devices, and sensors to communicate with each other. In smart factories, IoT facilitates seamless communication between production lines, maintenance systems, and supply chain operations, ensuring everything works in harmony.

Artificial Intelligence and Machine Learning: AI and machine learning are at the heart of predictive analytics and automation. These technologies allow factories to analyze vast amounts of data, identify patterns, and make intelligent decisions without human intervention. For example, AI can predict when a machine is likely to fail, preventing downtime and costly repairs.

Robotics and Automation: Robots have been used in manufacturing for years, but the latest robots are far more sophisticated. They’re equipped with sensors, AI, and machine learning capabilities that allow them to perform a variety of tasks—from assembling components to packaging products—without the need for constant human oversight.

Big Data and Analytics: Smart factories generate a massive amount of data every minute. Big data analytics tools allow manufacturers to sift through this data to make sense of it. These insights can drive decisions on everything from production schedules to supply chain logistics and quality control.

Cloud Computing: Cloud platforms enable manufacturers to access and analyze data in real-time, no matter where they are. With cloud computing, factory managers can monitor operations remotely, collaborate with teams across locations, and respond quickly to any issues that arise.

Key Players in the Smart Factory Market:

Several companies are leading the charge in transforming traditional manufacturing plants into smart factories. Industry giants like Siemens, General Electric, Rockwell Automation, Bosch, and Honeywell are spearheading innovations in automation, digital twins, and factory optimization. Additionally, smaller startups and technology firms are contributing to the growth of the market by offering specialized solutions such as AI-driven maintenance and advanced robotics.

The Global Impact of Smart Factories:

Economic Growth and Job Creation: The smart factory revolution isn’t just about robots replacing humans. In fact, while automation may reduce the need for certain manual jobs, it is also creating new opportunities in fields like AI, robotics, cybersecurity, and data analysis. This shift is resulting in the creation of new, high-tech jobs that require specialized skills.

Global Supply Chain Transformation: Smart factories can significantly improve global supply chains by enabling real-time tracking and monitoring of goods. They allow manufacturers to anticipate disruptions, better manage inventories, and respond more swiftly to market demands.

Emerging Markets: The adoption of smart factory technologies is growing rapidly in emerging economies, such as China, India, and Southeast Asia. As these countries invest in technology and innovation, they are positioning themselves as key players in the global manufacturing market, creating a new wave of competition and opportunity.

Challenges and Considerations:

While the smart factory market holds immense promise, there are challenges to consider:

High Initial Investment: For smaller manufacturers, the cost of upgrading to smart factory technologies can be a barrier. While the long-term savings and efficiency improvements are clear, the initial capital required for advanced technologies might be too much for some companies.

Cybersecurity Risks: With the increased reliance on digital technologies, smart factories face heightened risks of cyberattacks. Protecting sensitive data and ensuring secure communication between machines and devices is a top priority.

Integration Issues: Implementing smart factory solutions often involves integrating new technologies with legacy systems, which can be complex and time-consuming. Ensuring seamless integration across systems and processes is crucial for maximizing the benefits of a smart factory.

The Market for Smart Factories in the Future:

In the upcoming years, the market for smart factories is anticipated to continue expanding quickly due to developments in automation, IoT, and artificial intelligence. Future factories will be smarter, more efficient, and more flexible than ever before as more industries adopt digital transformation.

Smart factories will become the new norm as production demands shift toward efficiency, flexibility, and sustainability. Smart factories will be the foundation of the next industrial revolution, whether they are used to produce specialist medical equipment, advanced electronics, or daily consumer goods.

Smart Factory Market Smart Factory Market Forecast Smart Factory Market Analysis Smart Factory Market Demand Smart Factory Market value