Notifications

2 minutes, 25 seconds

-24 Views 0 Comments 0 Likes 0 Reviews

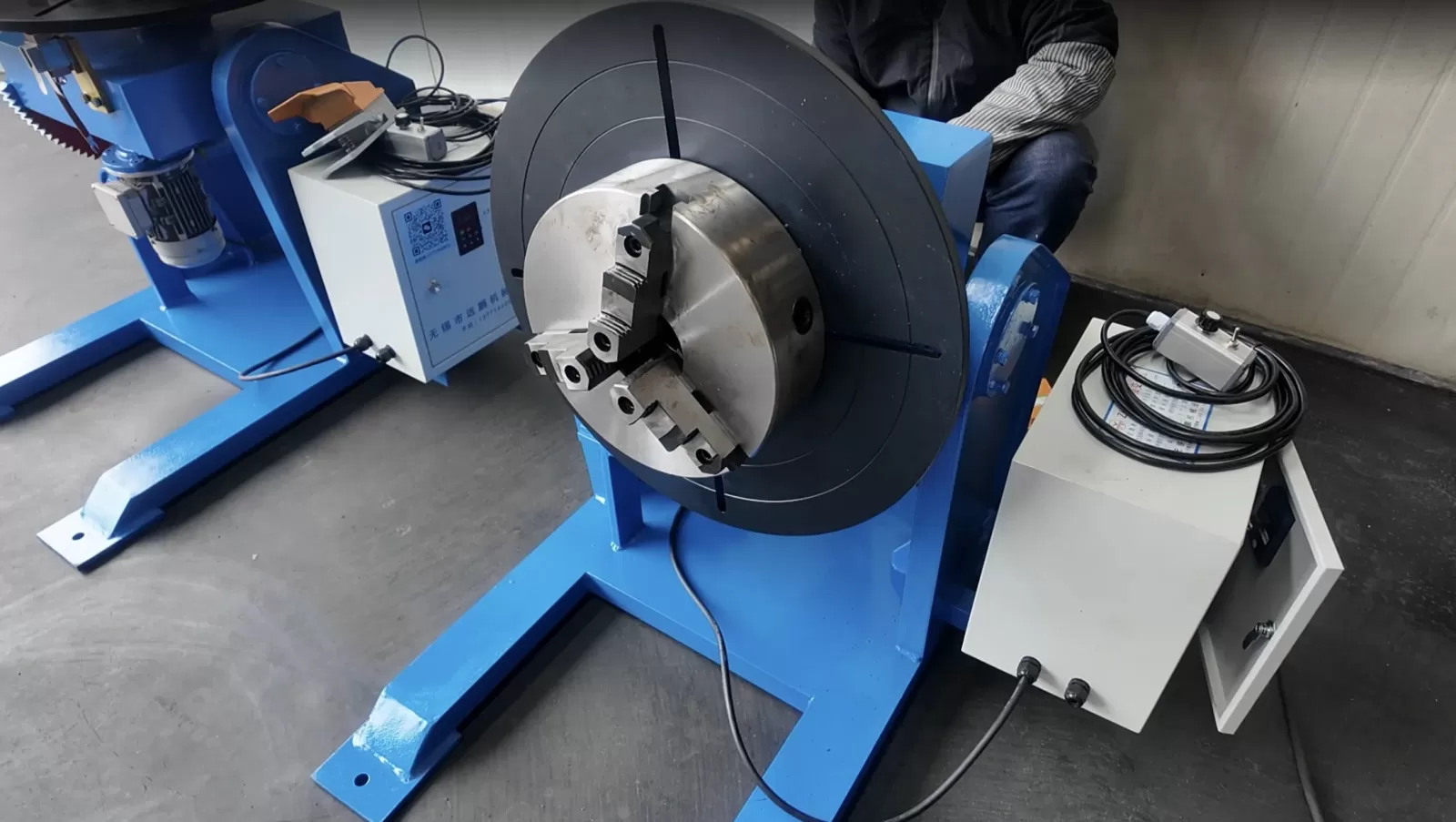

How Welding Positioner Fixtures Improve Welding Efficiency

Adjust Workpiece Orientation: Welding positioner fixtures can precisely position workpieces in the optimal welding angle, keeping seams in flat or horizontal positions instead of difficult overhead welds. This improves welding speed and quality.

Reduce Angle Changes: For complex structures, the welding positioner enables smooth rotation/tilting, maintaining consistent welding angles. This eliminates frequent operator adjustments, saving time and effort.

Quick Clamping & Positioning: Fixtures allow rapid, repeatable workpiece alignment, reducing setup time. For mass production, this ensures consistent weld quality and efficiency.

Precise Seam Alignment: Accurate positioning minimizes weld defects caused by misalignment, reducing rework and improving first-pass yield.

Integration with Robotic Systems: Welding positioners can synchronize with automated welders or robots through programmed motion control. This boosts speed and precision while reducing human error.

Faster Production Cycles: In automated lines, welding positioner fixtures enable rapid clamping, positioning, and welding, increasing throughput for mass production.

Minimize Part Flipping: For double-sided welds, the positioner’s rotation/tilt allows complete welding in a single setup, eliminating manual repositioning.

Easier Slag Removal: Well-designed fixtures and positioner movement make slag and spatter removal quicker, reducing cleanup time.

30-50% faster welding with optimal positioning

Higher first-pass yield (reduced rework)

Seamless automation with robotic welding systems

Lower labor costs by minimizing manual adjustments

Pressure vessel welding

Automotive component fabrication

Pipe and structural steel manufacturing

https://www.resizeglobal.com/improving-weld-quality-with-positioner-fixture.html