Notifications

7 minutes, 8 seconds

-25 Views 0 Comments 0 Likes 0 Reviews

In today's fast-moving construction world, the demand for smarter, faster, and more reliable project execution has never been greater. Deadlines are tighter. Budgets are stricter. And expectations? Through the roof. This pressure has led to a shift—a major one—towards using digital tools to manage, streamline, and optimize almost every stage of a project.

Whether it’s planning, estimating, or execution, technology is rewriting how teams collaborate and deliver. And it's not just about speeding things up. It's about doing it right the first time. Digital tools bring more than just convenience; they bring accuracy, visibility, and a level of control that manual processes simply can't match.

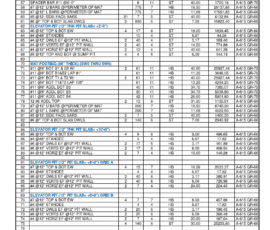

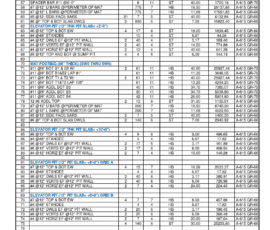

Let’s take construction estimation as a key example. Traditional methods involved piles of blueprints, hours of manual calculations, and a high chance of human error. Enter digital estimating platforms. These tools allow teams to generate fast, precise material takeoffs. For instance, rebar takeoff software has significantly improved the accuracy and speed of quantity estimation. Engineers can now model, visualize, and extract rebar quantities directly from digital drawings—saving countless hours and reducing costly mistakes. It's not just helpful; it’s a game changer.

A 2021 report by McKinsey & Company highlighted how digital transformation in construction can increase productivity by up to 15%. They cited that companies embracing digital workflows saw more predictable project outcomes and stronger collaboration across departments. What’s more, a study by Dodge Data & Analytics found that 63% of contractors using digital tools reported fewer schedule delays compared to those using traditional methods.

These aren't just stats—they’re a clear sign that digital tools are reshaping industry norms. Tools like Building Information Modeling (BIM), construction management platforms, and mobile field applications are becoming standard. With cloud-based access, teams on-site and in the office can stay aligned in real-time. This connectivity minimizes communication gaps and helps avoid costly rework.

Even safety, often a complex challenge on construction sites, benefits from digital intervention. Wearable tech and real-time data monitoring can help supervisors spot unsafe behaviors or conditions before they lead to incidents. AI-powered cameras and sensors are now being used to monitor compliance with safety gear regulations. The result? Fewer accidents, improved accountability, and a safer work environment for everyone.

Looking ahead, the role of digital tools is only going to grow. Especially with the rise of remote collaboration and data-driven decision-making. But the transition isn’t always seamless. One major hurdle is the learning curve. Many construction professionals, especially those used to paper-based systems, find the switch intimidating. That’s why successful adoption depends not just on the tools themselves, but on training, support, and a culture open to change.

Another critical area where digital tools shine is documentation and compliance. Digital document management systems allow for better tracking of project changes, permit statuses, and inspections. This helps firms stay organized and reduces the risks of non-compliance penalties. It also makes audits far less painful, as all necessary records are accessible in a few clicks.

Let’s not forget project forecasting. Tools powered by AI can now analyze past project data to predict future risks. This includes material shortages, potential delays, and cost overruns. With that kind of insight, decision-makers can proactively plan instead of constantly putting out fires. It’s not just smarter. It’s necessary for modern project success.

Beyond individual tools, integration is a big deal. A scattered collection of apps can create silos. The real efficiency boost comes when systems talk to each other—when a rebar takeoff software, for example, syncs with a project scheduling platform and feeds into the procurement system. That’s when you see real synergy. It eliminates redundant data entry and ensures every team is working off the same, up-to-date information.

Then there’s the broader industry shift towards sustainable building. Digital tools help track emissions, optimize energy use, and reduce material waste. They’re critical in helping construction firms meet green building standards and improve their ESG (Environmental, Social, and Governance) performance.

And when we talk about frameworks that shape building approaches, type five construction is an important category to mention. It’s one of the most common construction types for residential buildings, especially wood-frame ones. Understanding the limitations and opportunities of type five construction can be enhanced with digital simulations and fire performance modeling. These tools help architects and engineers ensure that buildings are compliant with fire codes and structural requirements—before a single nail is hammered.

The future of construction is clearly digital. And the companies that embrace this shift early are already seeing the benefits. Faster timelines. Fewer errors. Lower costs. Higher quality.

Digital construction tools Construction project efficiency Rebar takeoff software Type five construction Construction technology