Notifications

6 minutes, 16 seconds

-85 Views 0 Comments 0 Likes 0 Reviews

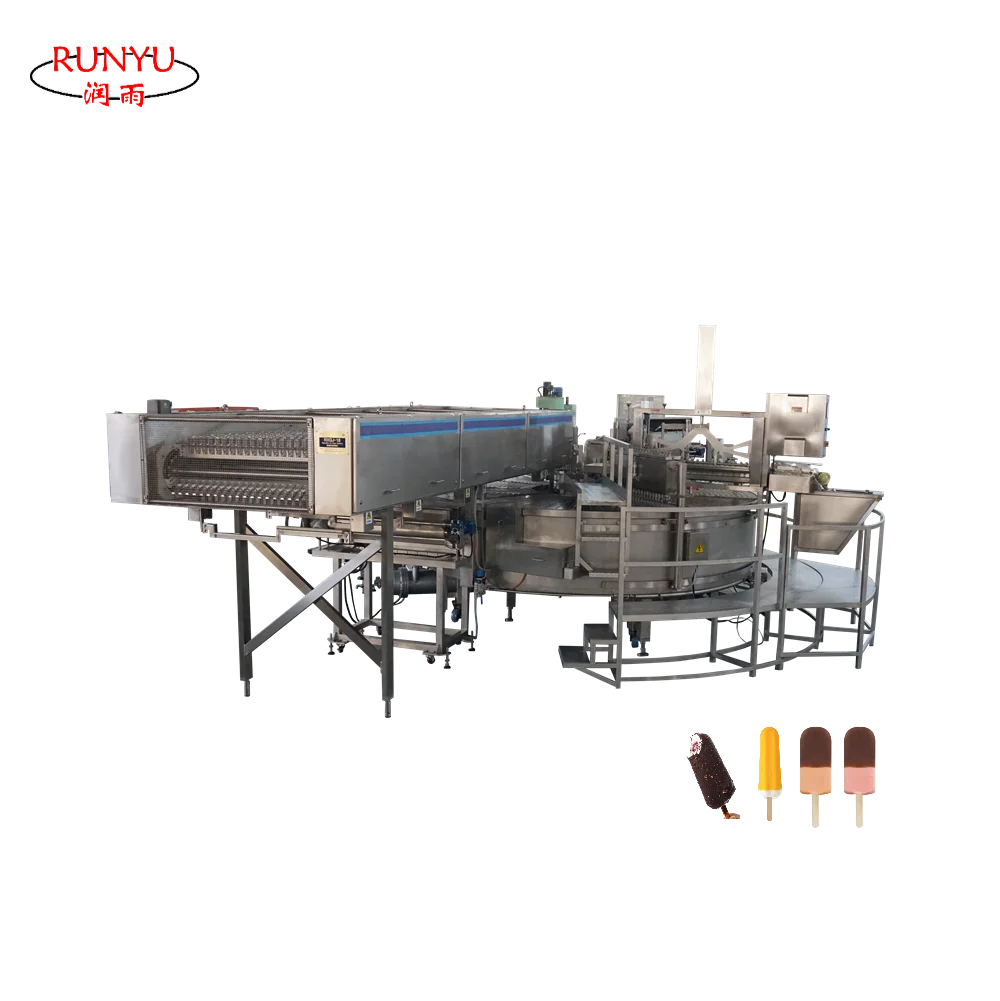

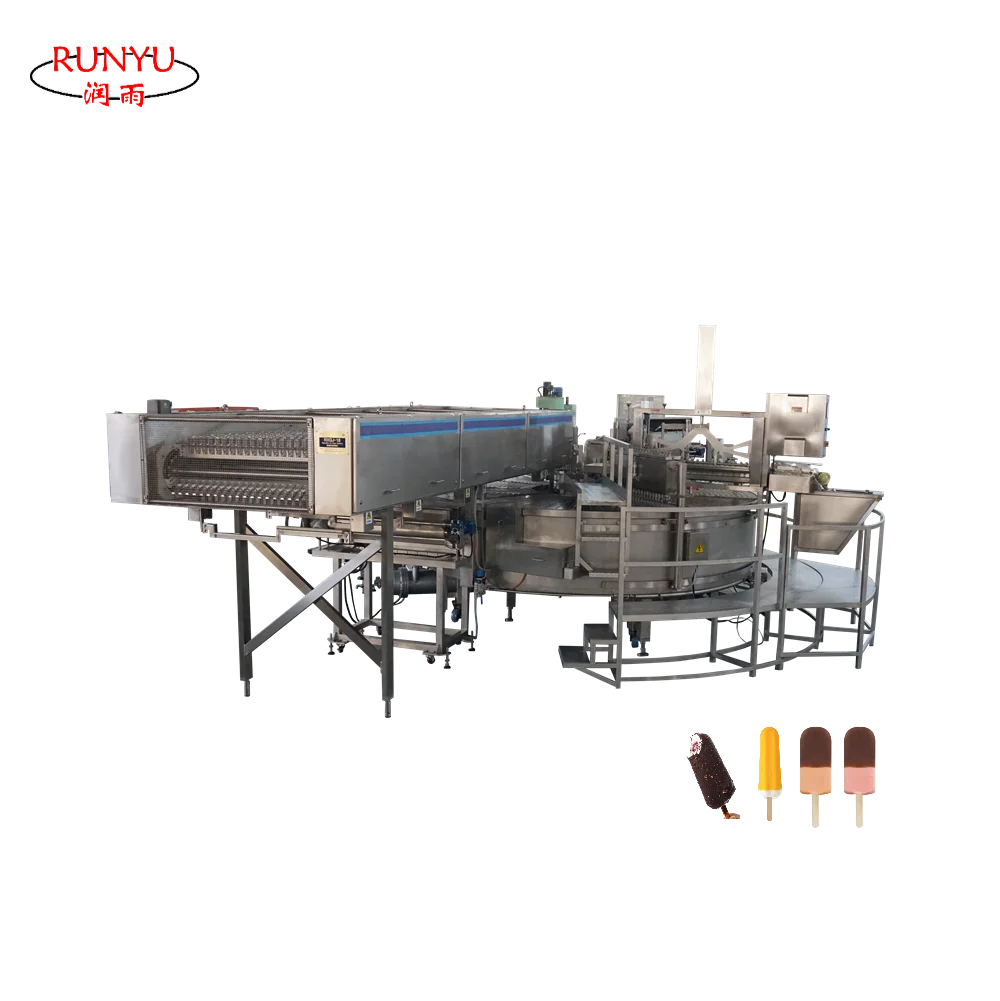

The Wuxi Danxiao Machinery rotary stick ice cream machine is a remarkable innovation in the food industry, particularly for businesses seeking to maximize production efficiency within limited spaces. This machine is designed to produce mold-ed ice creams or Popsicles in a streamlined, automated process. By understanding its working principle, businesses can leverage its unique selling points to enhance their operational capabilities.

The Rotary series ice cream machine is tailored for environments where space is a constraint but high production capacities are necessary. This machine combines automation with synchronization to ensure seamless operation from raw material input to finished product output. Each individual station within the machine moves automatically, reducing the need for manual intervention and minimizing downtime.

One of the most compelling selling points of the Rotary stick ice cream machine is its space-efficient design. In today's fast-paced business environment, real estate is often a premium. This machine is engineered to fit into compact spaces without compromising on production capacity. It allows businesses to maximize their floor space utilization, making it an ideal choice for small to medium-sized enterprises.

Despite its compact footprint, the Rotary stick ice cream machine boasts impressive production capabilities. The automated and synchronized movements of each station ensure continuous production, minimizing waste and maximizing output. This is particularly beneficial for businesses that need to meet high demand while maintaining consistent product quality.

Automation is another key feature that sets the Rotary stick ice cream machine apart. Each station within the machine operates independently yet in harmony with the others. This ensures that raw materials are processed smoothly from one station to the next, resulting in a seamless production line. The synchronization of movements further enhances efficiency, reducing the risk of errors and downtime.

The Rotary series ice cream machine is not limited to producing a single type of product. It can be configured to produce a variety of mold-ed ice creams or Popsicles, catering to diverse consumer preferences. This versatility makes it a valuable asset for businesses looking to expand their product offerings and attract a wider customer base.

Consistency is crucial in the food industry, especially when it comes to ice cream production. The Rotary stick ice cream machine ensures that each batch of ice cream or Popsicle meets the highest quality standards. The automated process eliminates human error, resulting in a uniform product that consumers can rely on. This consistency helps businesses build brand loyalty and maintain a competitive edge in the market.

The Rotary stick ice cream machine operates on a well-defined principle that transforms raw materials into finished products efficiently. Here's a step-by-step breakdown of the process:

Raw Material Preparation: The first step involves preparing the raw materials, such as mix, flavorings, and colorings. These ingredients are combined in the appropriate proportions to achieve the desired taste and texture.

Filling the Molds: Once the raw materials are ready, they are poured into the molds. The molds are specifically designed to hold the ice cream or Popsicle mixture until it freezes.

Insertion of Sticks: After filling the molds, sticks are inserted into each mold to serve as handles for the finished products. This step is crucial for ease of consumption and packaging.

Freezing Process: The molds containing the ice cream or Popsicle mixture are then moved to the freezing station. Here, they are exposed to low temperatures for a specified period to ensure complete freezing.

Ejection and Packaging: Once the ice creams or Popsicles are fully frozen, they are automatically ejected from the molds. They are then conveyed to the packaging station, where they are wrapped and labeled for distribution.

Quality Control: Throughout the process, quality control measures are in place to ensure that each batch meets the required standards. This includes checks on ingredient proportions, freezing temperatures, and packaging integrity.

The Rotary stick ice cream machine is a game-changer for businesses in the food industry. Its space-efficient design, high production capacity, automation, synchronization, versatility, and consistency in product quality make it an invaluable asset. By understanding its working principle and leveraging its unique selling points, businesses can streamline their ice cream production process, enhance operational efficiency, and meet the demands of a discerning consumer base.

https://www.wuxi-danxiao.com/the-working-principle-of-the-rotary-stick-ice-cream-machine.html

From Raw Materials to Finished Products: The Working Principle of the Rotary Stick Ice Cream Machine