Notifications

11 minutes, 7 seconds

-315 Views 0 Comments 1 Like 0 Reviews

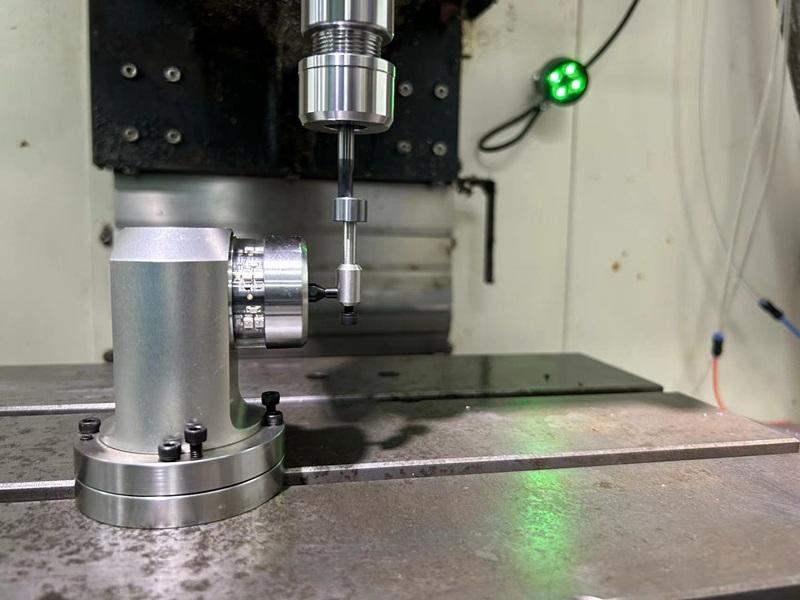

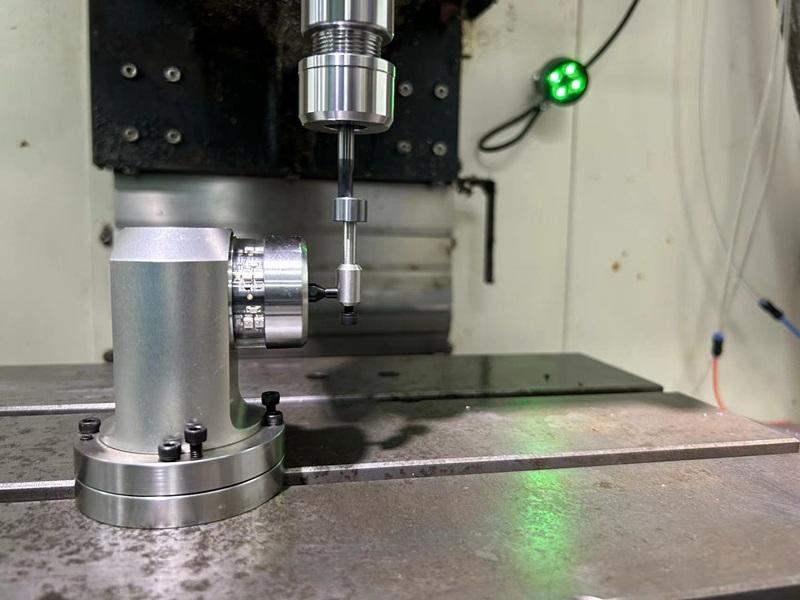

In the world of CNC machining, accuracy isn't just a preference—it’s a requirement. From aerospace components and medical implants to automotive parts and high-precision molds, every feature cut must meet exact specifications. Even a tiny deviation in tool length or diameter can lead to dimensional errors, poor surface finish, and costly rework. At SilverCNC, we help manufacturers tackle their most pressing challenges in productivity, accuracy, and automation. A tool setter probe, though often overlooked in comparison to major machinery upgrades, is one of the most impactful additions you can make to your CNC workflow. It’s a compact device—electronic or optical—that can drastically reduce human error, eliminate manual measurements, and enable automated, real-time, precision tool offsets with remarkable efficiency.

But not all tool setter probes are created equal. In fact, choosing the right tool setter probe makes the difference between mediocre results and consistent high-quality output.

A tool setter probe is a device used within a CNC machine to accurately measure the length, diameter, and wear of a cutting tool before or during the machining process. Mounted inside the machining envelope, the probe either touches or is contacted by the tool to automatically record precise dimensions, which are then used by the CNC controller to apply tool offsets.

There are two main types of tool setter systems:

Both methods enable CNC machines to calibrate tool measurements automatically, improving the consistency and quality of every part produced.

Misalignment, tool wear, or slight setup errors can have huge consequences—scrapped parts, missed deadlines, and lost revenue. Here's why tool setter probes are integral to machining performance:

By implementing a precision tool setter probe, manufacturers can automatically:

This reduces manual intervention, ensures greater consistency, and guarantees precise results, shift after shift.

Choosing the correct tool setter probe for your application results in measurable efficiency and quality improvements. Here’s what the right probe can do for your shop:

Tool length and diameter have a direct impact on the cutting path and depth. By measuring the tool automatically, a tool setter probe improves initial setup accuracy and removes human error from the equation. Machines consistently cut to correct depths—no surprises.

Manually setting tool lengths on twenty or more tools can take 30–60 minutes per shift. A high-quality tool setter can measure a full tool library in minutes—cutting setup time by over 80% and increasing spindle utilization.

Advanced tool setter probes can identify even minor tool wear during the job and compare pre- and post-operation measurements. If a tool has broken or is under length, the probe can trigger a machine stop or prompt a backup tool change.

With the ability to automatically verify and track tools, a CNC machine equipped with a robust tool setter system is ready for unattended (lights-out) operation, removing the need for constant operator supervision.

Accurate offsets and consistent dimensions reduce the number of parts that fall outside tolerance. That means fewer scrap and fewer expensive re-machining jobs.

Manual tool setting varies from person to person. A tool setter ensures standardized processes, improving consistency whether it’s the first shift or the third.

Also Read: The Benefits of Using a Tool Setter Probe [Infographic]

There are several types of tool setter probes to choose from. The best choice for your shop depends on your CNC configuration, operational scale, and accuracy requirements.

At SilverCNC, we offer a full range of contact and non-contact tool setter probes that cater to various industries and production scenarios.

The benefits of tool setter probes are applicable across a wide variety of machining tasks and industries:

Choosing the right tool setter probe is essential for achieving accurate tool measurement and consistent machining results. Key factors to consider include measurement precision, repeatability, durability, compatibility with your CNC machine, and ease of integration with existing systems. A reliable tool setter probe reduces setup time, minimizes tool wear, and helps maintain tight tolerances, ultimately improving productivity and machining efficiency.

Look for repeatability ratings under ±1 micron for high-end machining.

Resilient construction for chip/coolant environments; corrosion-resistant materials.

Ensure your CNC controller supports the interface, M-codes, and signal types required.

Make sure your post-processing software or CAM setup can fully utilize tool measurement data.

Choose a supplier that provides calibration kits, manuals, and support for long-term accuracy.

At SilverCNC, we engineer tool setter probes that deliver unparalleled reliability, accuracy, and ease of integration. Our product line includes:

Each unit is built with hardened materials, IP-rated sealing, and easily integrates with major CNC controllers like FANUC, Siemens, Haas, Heidenhain, and others.

If you're looking to increase accuracy, reduce setup time, and boost your CNC machine’s productivity, investing in a tool setter probe is one of the smartest moves you can make. This small, powerful tool eliminates guesswork, standardizes your process across shifts, and enables your CNC operation to run at peak performance.

Q1: Do I need a tool setter probe if I only run small batches?

Yes. Even for short runs, a tool setter improves setup speed, reduces error, and adds long-term value.

Q2: What kind of maintenance is required?

Regular cleaning with a soft cloth and routine calibration checks. SilverCNC provides guides for maintaining tip sensitivity and accuracy.

Q3: Can I retrofit a probe on my existing CNC machine?

Absolutely. Tool setter probes can be retrofitted on most CNC machines with available I/O and PLC access. SilverCNC offers installation support and wiring diagrams.

Q4: Which is better for me—laser or contact probe?

Laser probes offer higher accuracy and are best for shops doing high-volume or tight-tolerance work. Contact probes are sufficient for many standard applications.

Q5: How do I set up the probe in my CNC control software?

Depending on your controller, it involves defining a probing cycle using M-codes or macro programs. SilverCNC provides integration instructions for all major CNC brands.