Notifications

5 minutes, 29 seconds

-203 Views 0 Comments 0 Likes 0 Reviews

GV Mold has solidified its reputation as a premier provider of plastic injection molds, offering top-tier solutions tailored to meet the diverse needs of industries such as automotive, electronics, medical devices, and consumer goods. With a commitment to precision, efficiency, custom plastic injection mold and innovation, GV Mold ensures that every mold is crafted to the highest standards, enabling businesses to produce reliable and high-performing components at scale.

GV Mold specializes in high-volume injection molding, a process that is critical for mass-producing plastic components efficiently. By leveraging advanced technologies and multi-cavity molds, GV Mold enables clients to produce large quantities of identical parts in short cycle times. This approach not only reduces production costs but also ensures consistent quality across all units. High-volume injection molding is ideal for industries requiring scalability and precision, making GV Mold a trusted partner for large-scale manufacturing projects.

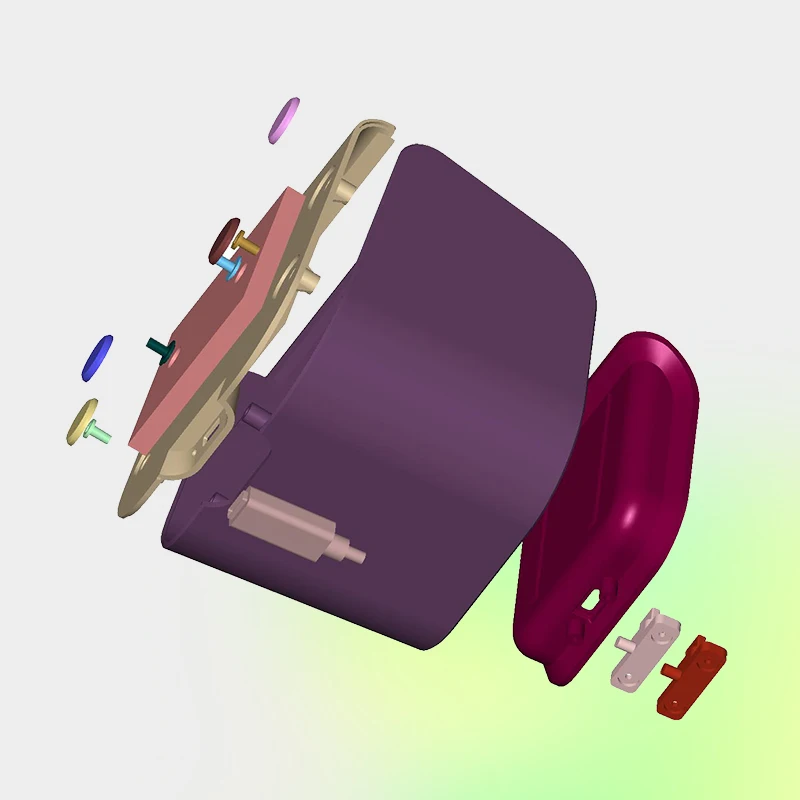

Tooling is the foundation of successful injection molding, and GV Mold excels in designing and constructing molds that meet exact specifications. Using computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies, the company creates molds with intricate geometries and tight tolerances. Materials such as high-grade steel or aluminum are selected based on production requirements, ensuring durability and reliability. GV Mold’s tooling expertise guarantees molds that perform optimally over extended production runs while minimizing defects and downtime.

One of GV Mold’s strengths lies in its ability to deliver customized solutions for a wide range of applications. Whether it’s lightweight automotive components or intricate medical devices, each mold is tailored to meet specific industry needs. For example, family molds allow for the simultaneous production of multiple parts with different designs, while overmolding techniques combine materials to enhance product functionality. This versatility ensures that GV Mold can address unique challenges across various sectors effectively.

GV Mold integrates Design for Manufacturing (DFM) and Mold Flow Analysis (MFA) into its processes to optimize production efficiency. DFM ensures that product designs are compatible with manufacturing constraints by addressing issues such as part geometry or material flow early in development. MFA simulates the behavior of molten plastic within molds to predict potential challenges like uneven cooling or air pockets. Together, these methodologies enhance productivity, reduce waste, and ensure consistent results across all production cycles.

Selecting the right material is crucial for achieving durable and high-performing plastic components. GV Mold provides expert guidance in choosing materials based on application-specific requirements such as strength, flexibility, heat resistance, or chemical compatibility. For instance, thermoplastics like polyethylene or polypropylene may be recommended for consumer goods due to their affordability and versatility. By aligning material properties with functional needs, GV Mold ensures that every product performs reliably while meeting cost considerations.

Quality assurance is central to GV Mold’s operations, ensuring that every mold meets stringent standards before entering production. The company employs rigorous inspection protocols using advanced tools like 3D scanning and automated measurement systems to verify accuracy and consistency. First article inspections (FAIs) are conducted to validate mold performance under real-world conditions. This dedication to quality has earned GV Mold the trust of leading manufacturers worldwide who rely on their expertise for critical projects.

GV Mold’s comprehensive approach makes them a preferred partner for businesses seeking top-tier plastic injection molding solutions. Their ability to provide end-to-end services—from design consultation to full-scale production—ensures seamless execution at every stage of a project. By combining technical expertise with innovative methodologies like DFM/MFA integration and custom tooling capabilities, GV Mold delivers products that exceed expectations while helping clients optimize their manufacturing processes.

With its commitment to precision engineering and customer satisfaction, GV Mold continues to lead the way in providing reliable plastic injection molds designed for success in today’s competitive industries.