Notifications

5 minutes, 10 seconds

-19 Views 0 Comments 0 Likes 0 Reviews

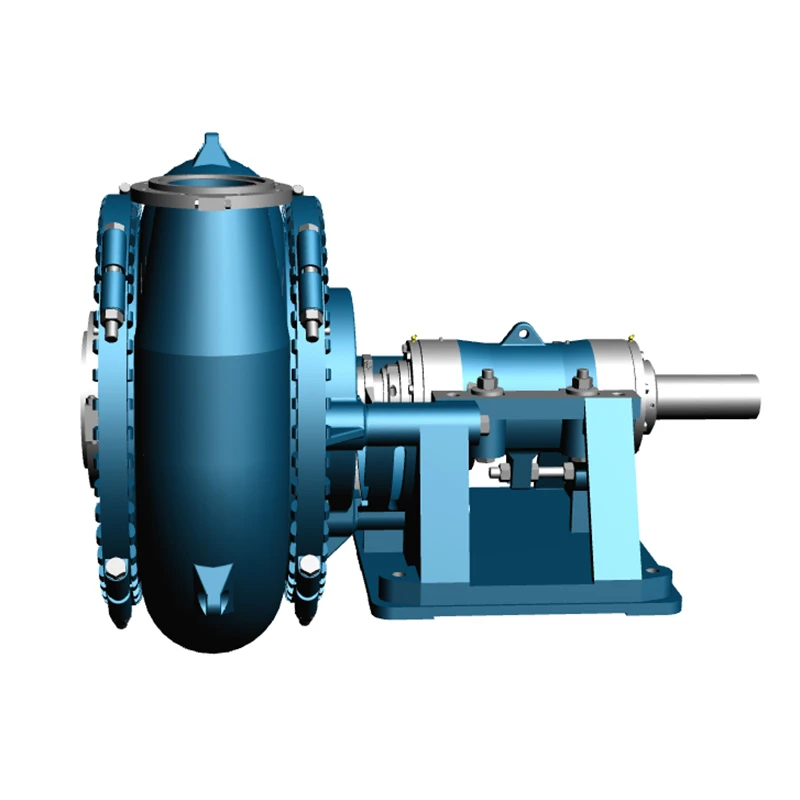

CNSME has become a recognized leader in the field of gravel pump manufacturing, setting industry benchmarks for durability, efficiency, and versatility. With a focus on centrifugal pump technology, CNSME’s gravel pumps are engineered to handle the most abrasive and challenging slurries, including sand, gravel, and other coarse materials. The company’s commitment to advanced engineering and high-quality materials ensures their pumps deliver consistent performance, even in the most demanding environments found on major construction, mining, and dredging projects worldwide.

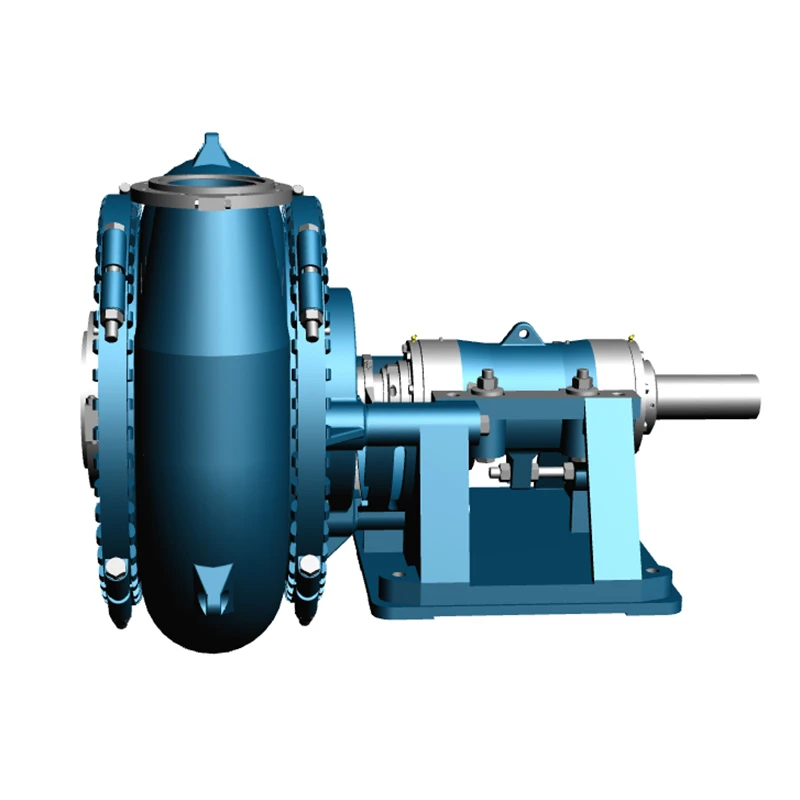

One of the hallmarks of CNSME gravel pumps is their use of high chrome alloy, specifically the A05 grade, for all critical wet-end components. This material offers exceptional hardness, with ratings between HRC 58-62, making it highly resistant to abrasion and corrosion. The result is a pump that maintains its structural integrity and efficiency over extended periods of heavy-duty use. Customers can also choose between metal or rubber linings, allowing for further customization based on the specific abrasiveness and chemical composition of the materials being pumped.

CNSME’s gravel pumps are designed with versatility in mind, making them suitable for a wide range of applications across the globe. Whether it’s sand excavation, hydraulic mining, cyclone feeds, tunneling, or aggregate transport, CNSME pumps are engineered to provide reliable service. The horizontal, single pump casing structure, secured with special clamps, allows for easy maintenance and installation, while the 360-degree adjustable outlet ensures flexible integration into any site layout. This adaptability has made CNSME a preferred choice for clients in Russia, Holland, Italy, and other regions where project requirements can vary significantly.

CNSME’s gravel pumps, such as the SG/150E (8/6E-G) model, are built for high-volume material handling, with capacities ranging from 126 to 576 cubic meters per hour and heads up to 45 meters. The wide flow channels and advanced impeller designs minimize clogging and maximize throughput, ensuring efficient operation even with large solids. These pumps are also equipped with heavy-duty bearings and adjustable impeller clearances, which help maintain optimal performance and extend service life, even during continuous operation in harsh conditions.

Understanding that every project is unique, CNSME offers a wide array of customization options. Clients can select from various shaft seal types—packing, expeller, or mechanical seals—depending on their operational needs. The pumps are available in multiple sizes and can be configured with different transmission methods, including V-belt, flexible coupling, gearbox, and hydraulic coupling drives. This flexibility allows CNSME to deliver pumps that are tailored to the specific demands of each application, ensuring the best possible performance and reliability.

CNSME’s reputation as a leading supplier is reinforced by its strong presence in international markets and its track record of supporting large-scale projects. Their pumps are widely used in mining, construction, mineral processing, and dredging industries, where they are valued for their long life, efficient operation, and ease of maintenance. The company’s ISO and CE certifications further attest to its commitment to quality and safety standards, making CNSME a trusted partner for companies around the world seeking reliable gravel pump solutions.

Beyond product excellence, CNSME is dedicated to providing professional support throughout the lifecycle of each pump. From initial consultation and selection to installation, maintenance, and spare parts supply, CNSME’s team of experts ensures clients receive the guidance and assistance needed for smooth, uninterrupted operations. This customer-focused approach, combined with robust engineering, has solidified CNSME’s status as a leading supplier of gravel pumps for global projects, especially for those interested in construction equipment and professional support for their operations.