Notifications

3 minutes, 57 seconds

-6 Views 0 Comments 0 Likes 0 Reviews

We are a Leading Control Valve Manufacturer in China, Delivering High-Performance Valves and Actuators Engineered to Meet a Wide Range of Industrial Applications.

In contemporary industrial settings, the effective management of fluid flow is paramount—driving demand for advanced and reliable valve technologies. Among these, diaphragm control valves stand out as essential components, offering exceptional versatility, leak-tight performance, and ease of maintenance across a wide range of applications.

Diaphragm valves operate using a flexible diaphragm that separates the fluid from the valve’s internal components. The diaphragm is actuated—typically pneumatically or hydraulically—causing it to lift or seat against a weir or straight-through body structure. This motion regulates fluid flow with precision, ensuring both tight shutoff and smooth modulation.

The integrity of the diaphragm seal makes these valves ideal for applications requiring zero contamination, corrosion resistance, or frequent sterilization.

Diaphragm valves are available in several configurations, including:

Weir Type: Most common; ideal for general-purpose flow control and easily cleaned or sanitized.

Straight-Through (Straightway) Type: Better for handling viscous fluids, slurries, or systems requiring full-bore flow.

Three-Way Type: Used in complex fluid routing systems for mixing or diverting flows.

For this overview, the focus is on the standard weir-type diaphragm valve, known for its compact size, economical design, and compatibility with a wide range of process media.

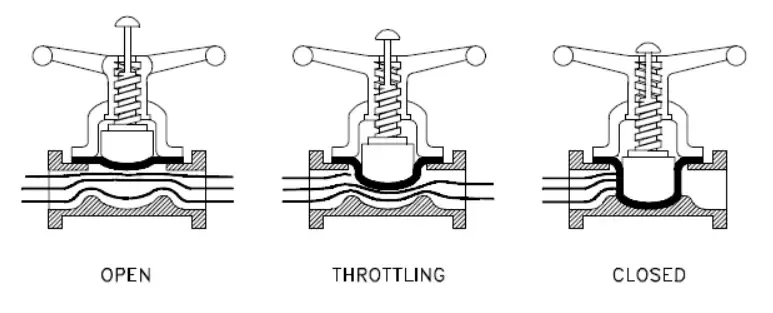

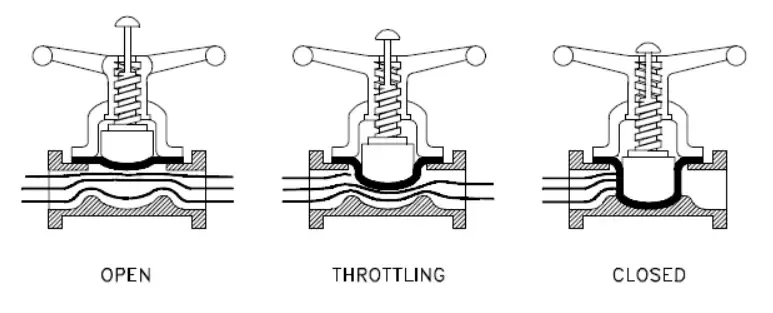

The valve operates by displacing the diaphragm:

Flow Open: When the actuator pulls the diaphragm away from the weir or seat, the valve opens, allowing fluid to pass.

Flow Closed: When the diaphragm is pressed down against the weir, it blocks the flow path, stopping fluid movement.

This simple mechanism provides accurate and reliable control of flow rates and is especially effective in sanitary or hazardous environments.

One key advantage of diaphragm valves is their ability to control flow in both directions, which allows:

Independent flow management: Precise control of input and output streams.

Supply-side regulation: Managing fluid or gas ingress into pressurized systems.

Exhaust-side control: Managing effluent or pressure release, essential for maintaining system balance and avoiding backpressure buildup.

In systems with limited volume or unidirectional requirements, diaphragm valves enable reliable, modulated control without compromising sealing performance.

✅ Leak-proof sealing (no stem packing)

✅ Isolation of actuator from process media

✅ Suitable for aggressive or corrosive fluids

✅ Hygienic design for food, pharma, and biotech

✅ Low maintenance with minimal moving parts

Diaphragm valves are foundational in modern fluid control systems. Their flexible, hygienic, and robust design makes them well-suited for sectors ranging from pharmaceuticals and food processing to chemical treatment and semiconductor manufacturing. With various configurations to suit specific flow and directional control needs, diaphragm valves offer a cost-effective, reliable, and clean solution for fluid regulation challenges.Know more about Google SEO Directory