Notifications

4 minutes, 15 seconds

-378 Views 0 Comments 0 Likes 0 Reviews

A sand washer, also known as a sand washing machine, is essential equipment in the mining, construction, and aggregate industries. Its primary function is to remove impurities, such as clay, silt, and dust, from sand and gravel materials, enhancing the quality and purity of the final product.

By improving the material's grading and reducing harmful substances, a sand washer ensures that the processed sand meets the strict standards required for construction projects, like concrete production and road building.

Types of Sand Washers

There are several types of sand washers available, each with unique features. The most common ones include spiral sand washers, bucket wheel sand washers, and trommel scrubber. Besides, there are vibrating sand washer, combined sand washing systems.

Spiral Sand Washer

Principle: Sand is tumbled and scrubbed in water by rotating screw blades, with impurities removed via overflow. Clean sand is discharged from the opposite end.

Features:

Simple structure, low maintenance costs.

Integrates washing, dewatering, and classification.

Suitable for medium/small capacity

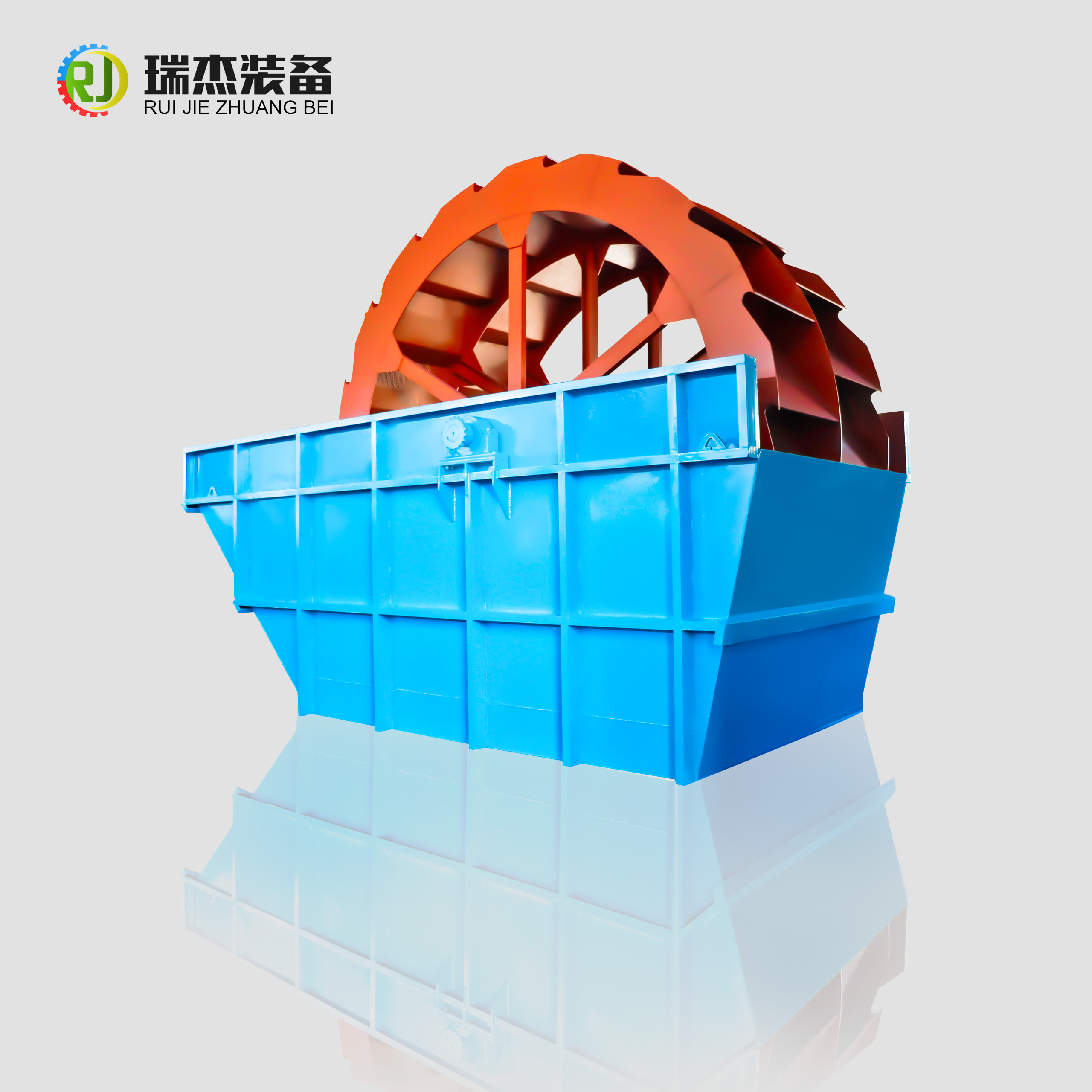

Bucket Wheel Sand Washer

Principle: Rotating buckets scoop sand slurry from a tank. Water drains through screens during lifting, while impurities overflow.

Features:

High washing efficiency, especially for clay-rich sand.

Large capacity (up to 500 t/h) with excellent dewatering.

Higher energy consumption and large footprint.

Suitable for large-scale aggregate plants, manufactured sand production.

Trommel Scrubber Washer

Principle: Sand is lifted and dropped inside a rotating drum, with water scrubbing away impurities.

Features:

Intensive scrubbing for high-clay or aggregated sand.

May integrate screening (e.g., gravel removal).

Flexible capacity but high water usage.

Suitable for mining, construction waste recycling.

How to Select a Right Sand Washer Machine

When choosing a sand washer, several factors need consideration. First, the production capacity should match the project's scale. A large - scale construction site demands a high - capacity washer to meet the material supply. Second, the nature of the raw materials matters. For materials with high clay content, a more powerful washing mechanism is required. Additionally, maintenance costs and energy efficiency are crucial. Equipment with low maintenance requirements and energy - saving features reduces long - term operational expenses.

Advantages of Spiral Sand Washers

Among these types, spiral sand washers stand out with distinct advantages. They feature a continuous washing process, enabling high - volume production. The spiral structure provides a longer washing path, ensuring thorough cleaning of sand particles. Moreover, their simple design reduces the likelihood of breakdowns, leading to lower maintenance costs. Spiral sand washers are also highly adaptable, suitable for various sand and gravel materials, making them a preferred choice for many aggregate processing plants.

In conclusion, sand washers are indispensable in modern industrial production, significantly improving the quality of sand and gravel products. Understanding different types, selection criteria, and the unique benefits of equipment like Ruijie equipmentspiral sand washers helps industries make informed decisions. By choosing the right sand washer, companies can enhance production efficiency, reduce costs, and contribute to high - quality construction projects.

https://www.ruijie-equipment.com

Mobile/WhatsApp: +8617878005688

Email:R01@ruijie-equipment.com

Sand washer #sand washing machine #spiral sand washer # screw sand washing machine #bucket wheel sand washer # sand washing