Notifications

7 minutes, 30 seconds

-40 Views 0 Comments 0 Likes 0 Reviews

Leading Chinese Manufacturer of Industrial Valve Seal Kits Offers Low-Emission Valves and High-Performance Packing & Seal Materials for Demanding Applications.

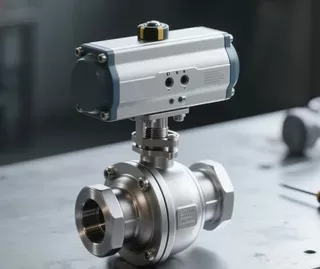

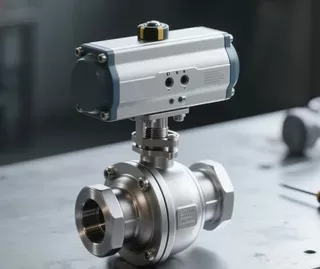

In modern industrial production, fluid transmission and control are fundamental to many process workflows. Industries such as chemical manufacturing, petroleum refining, natural gas processing, and food production all require precise, efficient, and reliable valve systems to regulate fluid flow, pressure, and direction. Among various valve options, pneumatic ball valves stand out for their speed, accuracy, and operational simplicity, making them a preferred choice for industrial fluid control. This article explores their working principles, classifications, advantages, and applications to provide a comprehensive understanding of this essential control device.

A pneumatic ball valve is an automated valve system consisting of a ball valve and a pneumatic actuator. The ball valve component uses a rotating spherical disc to open or close the flow passage. When the ball is turned 90°, it either fully opens or seals the passageway. The pneumatic actuator, powered by compressed air, drives this rotation quickly and accurately, enabling remote or automated control of the valve.

These valves often include additional accessories such as solenoid valves, air treatment units, limit switches, and positioners. These components enhance functionality, allowing for both on-site control and remote centralized management. With integration into control systems, operators can manage valves from a safe distance, improving both safety and operational efficiency.

The operating mechanism of pneumatic ball valves is straightforward yet highly efficient. When compressed air enters the actuator, it drives the internal piston, causing the ball to rotate between the open and closed positions. This motion requires minimal torque and can be completed in fractions of a second. For flow regulation applications, a valve positioner can be added to finely control the degree of opening, thus managing the flow rate with high precision.

Pneumatic actuators come in two main types:

Single-Acting Actuators: These actuators contain an internal spring. When air pressure is applied, the actuator moves the valve. Upon loss of air or power, the spring automatically returns the valve to a preset fail-safe position (open or closed). This is critical in hazardous applications where automatic shutoff is necessary during emergencies.

Double-Acting Actuators: These require air pressure to both open and close the valve. While they lack fail-safe functionality during power loss, their simpler design is suitable for lower-risk environments and offers cost advantages.

Based on functionality, pneumatic ball valves are generally divided into two categories:

On-Off Type

Featuring an O-type ball core, these valves are designed for rapid and reliable opening and closing. With a full-bore design matching the pipeline diameter, they offer excellent sealing performance, ideal for applications requiring swift fluid isolation.

Regulating Type

These incorporate a V-type ball core with a V-shaped notch, allowing for fine control of flow rates. When paired with a positioner, they can precisely regulate fluids—even those containing fibers or particulates—making them suitable for process control environments requiring variable flow.

Pneumatic ball valves are widely used due to several standout benefits:

Fast Response Time

With switching times as short as 0.05 seconds, they are ideal for emergency shutoff scenarios.

Ease of Operation

Simple to automate and integrate into centralized systems, they reduce manual workload and support scalable control.

Superior Sealing

The ball and sealing surfaces maintain tight contact, resisting erosion and leakage even under high pressure, vacuum, or particulate-laden media.

Broad Applicability

Compatible with media ranging from water and gas to acids and hazardous chemicals, and operational across wide pressure and temperature ranges.

Compact Design and Easy Maintenance

Lightweight and space-saving, with replaceable sealing components for convenient servicing. The sealing surface is shielded from media during operation, extending service life.

Thanks to their versatility, pneumatic ball valves are essential across many sectors:

Chemical Industry

Control aggressive or hazardous chemicals with precision and safety.

Petroleum & Natural Gas

Ensure reliable sealing and rapid shutoff to prevent leaks or fires in high-pressure environments.

Food Processing

Maintain sanitary conditions with easy-to-clean valves that prevent contamination.

Pharmaceutical Manufacturing

Meet stringent cleanliness and precision requirements in drug production.

Water Treatment

Deliver consistent performance in corrosive and complex water management scenarios.

Choosing the appropriate valve requires evaluating several factors:

Operating Conditions: Determine whether fast shutoff (on-off type) or variable control (regulating type) is needed.

Medium Characteristics: Account for temperature, pressure, and chemical properties to select compatible materials and designs.

Actuator Type: Choose single-acting for safety-critical operations or double-acting for general use.

Quality and Brand: Opt for reputable manufacturers with reliable quality control and after-sales support.

To ensure reliability and extend the valve's life, follow these maintenance guidelines:

Routine Inspections: Check for leaks, actuator function, and accessory integrity.

Cleaning & Lubrication: Regularly clean and lubricate moving parts to prevent wear and contamination.

Replace Worn Components: Monitor and replace seals and springs as needed.

Adhere to Proper Operation: Avoid overpressure and misuse to reduce mechanical stress.

Pneumatic ball valves are indispensable in modern industrial fluid control systems. Their fast action, tight sealing, and adaptability make them a robust solution for a wide variety of applications. As technology evolves, these valves will continue to become more intelligent, efficient, and environmentally friendly. Proper selection, installation, and maintenance are key to maximizing their performance and ensuring safe, efficient industrial operations.Know more about Google SEO Directory

China Valve Manufacturer Valve Packing Manufacturer China Valve Seals Valve Seal Kits