Notifications

8 minutes, 25 seconds

-272 Views 0 Comments 0 Likes 0 Reviews

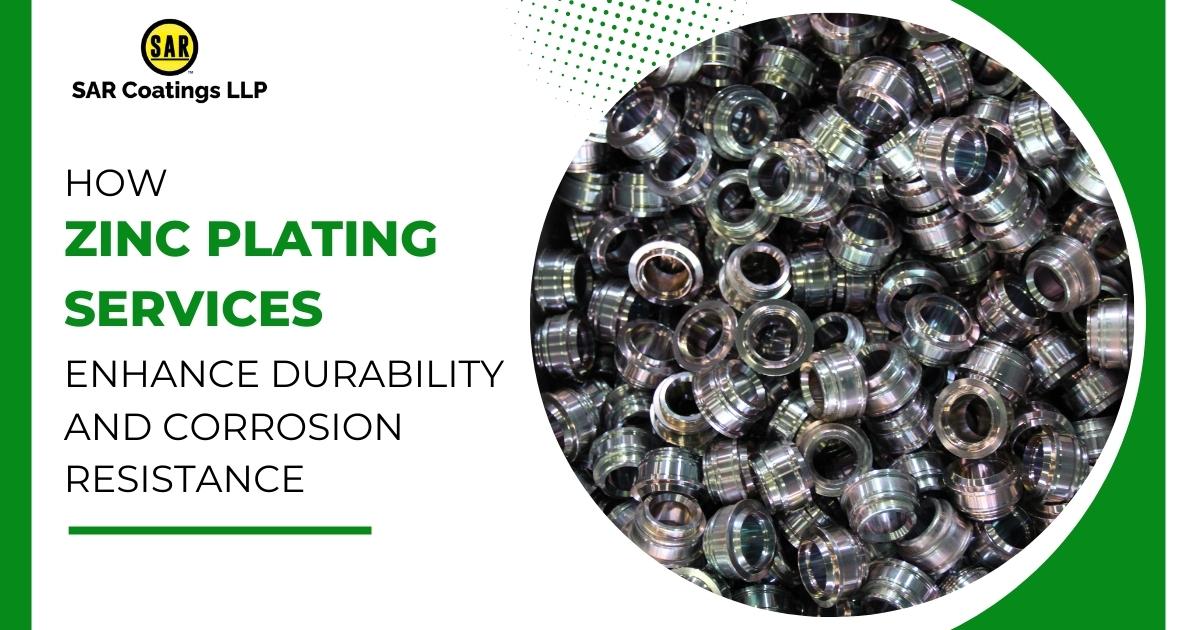

Zinc plating is an essential technology used in the preservation of essence and thus makes them robust and resistant to rust. The process involves applying a precisely measured electrical current to produce a nanoscale coating on the essence face, therefore guarding the essence from erosion.

Zinc plating offers several advantages that make it an ideal choice for essence protection

Long- lasting Protection The zinc coating acts as a hedge, precluding erosion and extending the lifetime of the essence.

Sacrificial Defense In case of any damage to the coating, the zinc subcaste offerings itself to cover the beginning essence.

Eco-Friendly result Zinc plating service uses recyclable accoutrements and energy-effective ways, minimizing its impact on the terrain.

protean operation This system is extensively used in colorful diligence similar as automotive, construction, and manufacturing.

In this companion, we will explore how zinc plating not only safeguards essence but also contributes to sustainable practices. We will claw into the details of this process and its benefits for both diligence and the earth.

Zinc plating is a process that uses electricity to apply a subcaste of zinc onto essence shells. This subcaste acts as a strong hedge, guarding the essence from rust and damage caused by the terrain.

Before the zinc can be applied, the essence face needs to be duly set. This involves

drawing the face to remove any canvases , dirt, or pollutants

Using chemicals to degrease the face for thorough sanctification

Applying acid to spark the face and insure better adhesion of the zinc

Once the face is set, the factual plating process begins. This includes

Immersing the essence object in a result that contains a high attention of zinc

Applying an electrical current to the result

Allowing zinc ions to resettle and settle onto the essence face

Creating a invariant subcaste of zinc coating through controlled deposit

After the plating process is complete, fresh treatments may be performed to enhance protection and insure quality. These way involve

Applying a chromate conversion coating for added erosion resistance

Sealing the carpeted face to help humidity doorway

Conducting examinations and tests to corroborate coating consistence and quality

The purpose of thismulti-step process is to produce a durable and long- lasting defensive subcaste on essence factors, making them more resistant to erosion in colorful artificial operations.

The strategic selection of zinc plating services delivers substantial advantages for artificial operations

Zinc's sacrificial anode medium creates an electrochemical guard

The zinc coating corrodes at a rate of 1/ 30th compared to sword

Protection continues indeed when the base essence becomes exposed

tone- mending parcels help rust conformation at scratched areas

2. Proven continuity in Demanding diligence

Automotive Applications

Underbody factors maintain integrity despite road swab exposure

Brake system corridor repel erosion for 10 times

Fasteners retain strength in high- humidity conditions

Construction Sector Performance

Structural sword rudiments repel severe rainfall conditions

structure tackle maintains functionality in littoral surroundings

Ground factors show 50 longer service life

pervious zinc coating structure enables

40 stronger makeup adhesion

Reduced makeup consumption

Extended coating continuance

Livery face appearance

Zinc plating costs 25 lower than indispensable coating styles

minimum conservation conditions reduce long- term charges

Extended product lifetime decreases relief frequence

Quick processing time pets up product schedules

Compatible with colorful essence substrates

sword factors

Iron accoutrements

Essence fasteners

tackle particulars

Suitable for both small corridor and large assemblies

Adaptable to complex shapes and intricate designs

The zinc plating process combines these benefits with dependable performance across different artificial operations, making it a favored choice for manufacturers seeking durable, cost-effective face protection.

Zinc plating services are leading the way in sustainable essence protection results, offering

Longer Product lifetime The sacrificial protection medium extends the lifetime of essence factors

Cost-Effective Protection Reduced conservation requirements and relief frequentness

Environmental Benefits High recyclability and lower energy consumption during processing

Assiduity elaboration The shift towardeco-friendly druthers demonstrates the assiduity's commitment to sustainability

Choosing zinc plating is a smart decision for businesses looking to balance performance with environmental responsibility. As technology improves and environmental norms change, zinc plating remains a trusted, sustainable result for essence protection in colorful diligence.

What's zinc plating and why is it important?

Zinc plating is a process that applies a defensive subcaste of zinc onto essence substrates to enhance their continuity and erosion resistance. This system not only protects the beginning essence from environmental factors but also contributes to a further sustainable future.

How does the zinc plating process work?

The zinc plating process involves several way, including face medication of the essence substrate, followed by electrodeposition where zinc is applied as a defensive hedge. Zinc acts as a sacrificial anode, meaning it corrodes before the beginning essence, furnishing superior protection against rust and declination.

What are the benefits of choosing zinc plating services for my systems?

Choosing zinc plating services offers exceptional erosion resistance due to zinc's sacrificial anode part, enhanced continuity in harsh surroundings( as seen in automotive and construction diligence), and bettered makeup adhesion thanks to its pervious structure which benefits both aesthetic and functional rates.

Is zinc plating environmentally friendly?

Yes, zinc plating is considered environmentally friendly due to several factors. Zinc is recyclable, making it a sustainable choice for coatings. also, ultramodern processing ways are designed for energy effectiveness, serving manufacturing practices while reducing environmental impact.

What inventions are shaping the future ofeco-friendly zinc plating processes?

inventions ineco-friendly zinc plating include the use of trivalent chromium as a safer volition to dangerous substances, alongside advancements in technology and ways that ameliorate the environmental footmark of zinc plating services.

Why should businesses borroweco-friendly practices like zinc plating?

espousingeco-friendly practices similar as zinc plating is pivotal for businesses because it not only ensures long- lasting protection for products but also aligns with sustainability pretensions. This approach helps reduce environmental impact while enhancing product performance and continuity.