Notifications

6 minutes, 20 seconds

-16 Views 0 Comments 0 Likes 0 Reviews

Selecting the right CNC machining service provider is a critical decision for businesses that rely on precision manufacturing. Whether you need custom prototypes, small production runs, or large-scale manufacturing, the quality and efficiency of the machining provider can significantly impact your final product. With so many options available, it is essential to consider various factors to ensure that you partner with a reliable, skilled, and cost-effective provider. Evaluating aspects like technical capabilities, material expertise, turnaround time, and customer support can help you make the best choice for your manufacturing needs.

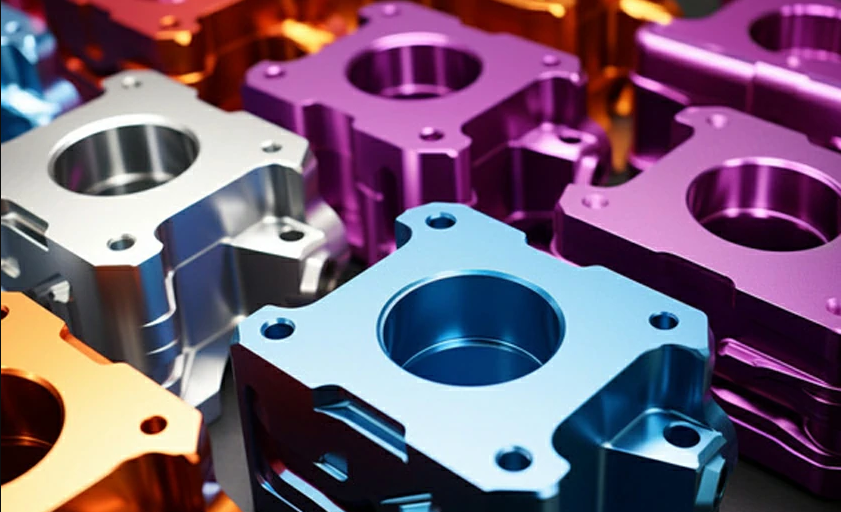

One of the first factors to evaluate when choosing a cnc machining services service provider is their technical expertise and the type of equipment they use. Advanced CNC machines, such as multi-axis milling and turning centers, allow for greater precision and efficiency. Providers with a range of modern CNC machines can handle complex designs and tighter tolerances, ensuring high-quality results. Additionally, checking whether the company offers secondary processes like finishing, coating, and assembly can be beneficial if your project requires additional work beyond machining.

Different cnc machining services projects require different materials, from metals like aluminum, stainless steel, and titanium to plastics and composites. It is crucial to select a provider with experience in working with the specific material needed for your project. Some providers specialize in machining certain materials and have the necessary tools and knowledge to handle them efficiently. A provider’s ability to recommend the best material for durability, cost-effectiveness, and performance can add value to your project and improve the final product's quality.

A CNC machining service provider’s industry experience can make a significant difference in the quality and reliability of their work. Companies that have served industries such as aerospace, medical, automotive, and electronics often have a deep understanding of industry-specific requirements. Certifications such as ISO 9001, AS9100 (for aerospace), and ISO 13485 (for medical devices) demonstrate a commitment to quality control and regulatory compliance. Working with a certified provider ensures that your parts meet high standards and industry regulations.

Timely delivery is crucial in manufacturing, especially when working on tight deadlines or large-scale production. It is important to assess a provider’s ability to meet your required turnaround time without compromising quality. Factors like in-house production capacity, workforce efficiency, and supply chain management influence how quickly orders can be fulfilled. Asking about lead times for prototypes and mass production can help you determine whether a provider can meet your schedule and production demands.

Consistent quality is essential in CNC machining, as even small errors can lead to defective parts and production delays. A reliable CNC machining service provider should have strict quality control measures in place, including inspections, tolerance checks, and testing procedures. Many top-tier providers use Coordinate Measuring Machines (CMM) and other advanced inspection tools to ensure precision and accuracy. Requesting information about their quality assurance processes can give you confidence in their ability to deliver flawless parts.

While cost should not be the sole deciding factor, it is important to compare pricing among different CNC machining providers to ensure you are getting the best value for your investment. Some providers may offer lower prices but compromise on quality or service. Look for a provider that offers a transparent pricing structure with detailed cost breakdowns, including material costs, machining time, and additional services. Understanding pricing factors can help you avoid hidden fees and make an informed decision that balances cost and quality.

Strong customer support and effective communication are essential when working with a CNC machining provider. A company that responds quickly to inquiries, provides clear project updates, and addresses concerns efficiently can make the entire process smoother. Reading customer reviews and testimonials can provide insight into a provider’s reliability and reputation. Positive feedback from previous clients indicates a strong track record, while negative reviews may highlight potential issues to watch for. Choosing a provider with excellent customer service ensures a better overall experience.

Choosing the right CNC machining service provider requires careful evaluation of several factors, including technical capabilities, material expertise, industry experience, and turnaround time. Prioritizing quality control, transparency in pricing, and strong communication can help ensure a successful partnership. By conducting thorough research and considering your specific project needs, you can select a CNC machining provider that delivers precision, efficiency, and reliability, ultimately contributing to the success of your manufacturing operations.