Notifications

5 minutes, 51 seconds

-120 Views 0 Comments 0 Likes 0 Reviews

HiTo Engineering is a leading provider of continuous galvanizing technology, offering a range of innovative solutions to enhance the durability and corrosion resistance of steel coils. The company's continuous galvanizing technology is designed to provide a robust and long-lasting protective coating for steel coils, ensuring that they remain in good condition throughout their lifecycle. With a strong focus on quality, sustainability, and environmental responsibility, HiTo Engineering has established itself as a trusted partner for businesses seeking to enhance coil protection and reduce the risks associated with corrosion.

The Importance of Coil Protection

Coil protection is a critical aspect of steel continuous galvanizing line production, as it helps to prevent corrosion and damage during storage, transportation, and processing. Corrosion can lead to significant losses in terms of material waste, production downtime, and maintenance costs. HiTo Engineering's continuous galvanizing technology provides a reliable and effective solution for coil protection, ensuring that steel coils remain in good condition throughout their lifecycle. The company's technology is designed to meet the specific needs of various industries, including construction, automotive, and manufacturing, where corrosion resistance and durability are essential.

HiTo Engineering's Continuous Galvanizing Process

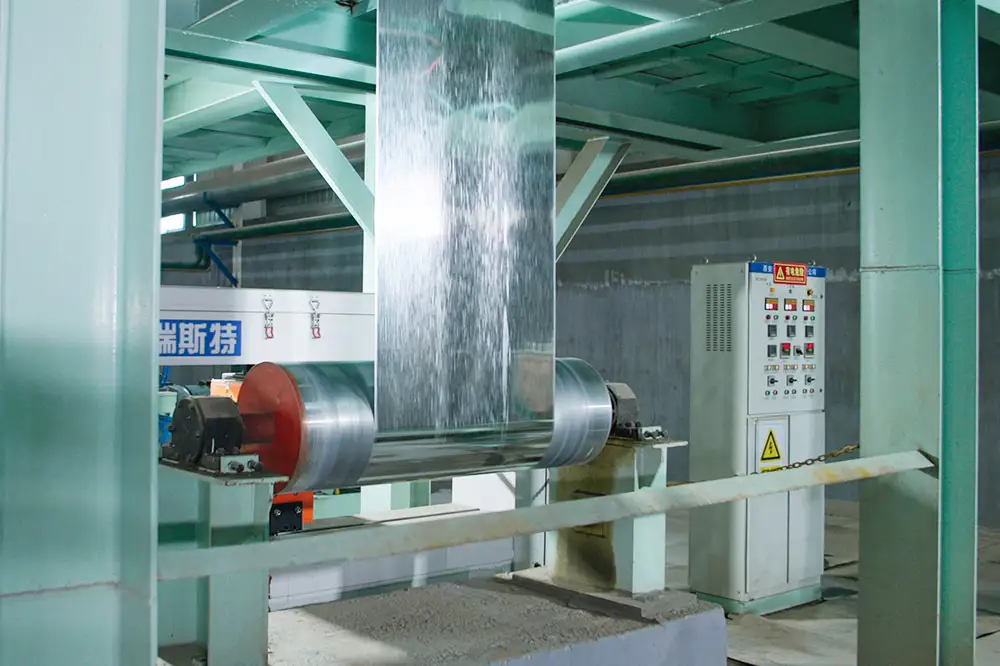

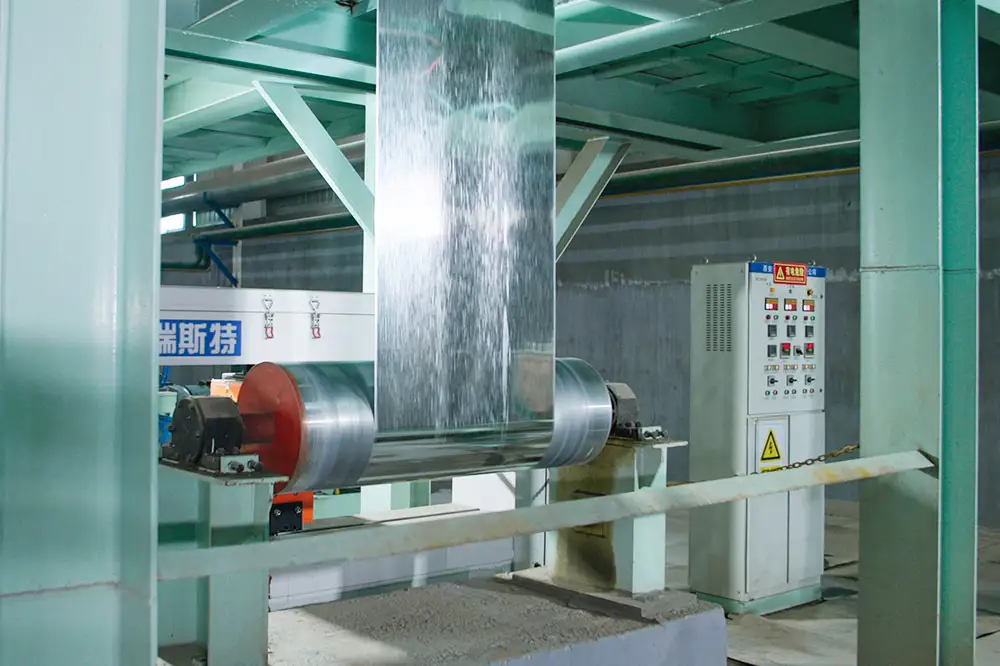

HiTo Engineering's continuous galvanizing process involves the application of a zinc coating to steel coils, providing a robust and long-lasting protective barrier against corrosion. The process begins with the preparation of the steel surface, which is cleaned and treated to ensure a strong bond between the steel and the zinc coating. The steel is then passed through a series of rollers, where it is coated with a layer of zinc. The zinc coating is then treated with a series of chemicals to enhance its adhesion and corrosion resistance.

Benefits of Continuous Galvanizing

The benefits of continuous galvanizing include enhanced corrosion resistance, improved durability, and increased lifespan of steel coils. Continuous galvanizing also provides a cost-effective solution for coil protection, reducing the need for frequent maintenance and replacement of damaged coils. Additionally, HiTo Engineering's continuous galvanizing technology is designed to be environmentally friendly, minimizing waste and reducing the environmental impact of the galvanizing process.

Industry Applications

HiTo Engineering's continuous galvanizing technology has a wide range of industry applications, including construction, automotive, and manufacturing. The company's solutions are used to protect steel coils used in building frames, roofing, and cladding, as well as in the production of automotive parts, such as body panels and chassis components. HiTo Engineering's continuous galvanizing technology is also used in the manufacturing industry, where it is used to protect steel coils used in the production of machinery, equipment, and consumer goods.

Quality Control and Assurance

HiTo Engineering is committed to delivering high-quality continuous galvanizing solutions that meet the exacting standards of its clients. The company's quality control and assurance processes involve rigorous testing and inspection to ensure that every galvanized coil meets the client's specifications. HiTo Engineering's team of professionals closely monitors every stage of the galvanizing process, from preparation to finishing, to ensure that the final product is of the highest quality. The company's quality control and assurance processes also involve continuous improvement, enabling it to refine its processes and improve its products over time.

Sustainability and Environmental Responsibility

HiTo Engineering is committed to sustainability and environmental responsibility, and its continuous galvanizing technology is designed to minimize waste and reduce the environmental impact of the galvanizing process. The company's solutions are designed to reduce energy consumption and emissions, making them a more environmentally friendly solution for coil protection. HiTo Engineering's continuous galvanizing technology also promotes the use of recycled materials, reducing the need for raw materials and minimizing waste.

Conclusion

In conclusion, HiTo Engineering's continuous galvanizing technology is a reliable and effective way to protect steel coils from corrosion, providing a robust and long-lasting protective coating that enhances durability and lifespan. The company's expertise in continuous galvanizing has enabled it to develop a range of innovative solutions that meet the specific needs of various industries, including construction, automotive, and manufacturing. With a strong focus on quality, sustainability, and environmental responsibility, HiTo Engineering has established itself as a trusted partner for businesses seeking to enhance coil protection and reduce the risks associated with corrosion