Notifications

4 minutes, 25 seconds

-27 Views 0 Comments 0 Likes 0 Reviews

Maintaining a clean and stationary environment is absolutely vital in sectors including healthcare, electronics manufacture, medicines, and semiconductor processing. Safety, compliance, and product integrity depend critically on many instruments and techniques including room ionisers, autoclaves, ESD testing, ESD audits, static control methods, and AMC analysers.

1. Eliminating Static Charges: Room Ioniser

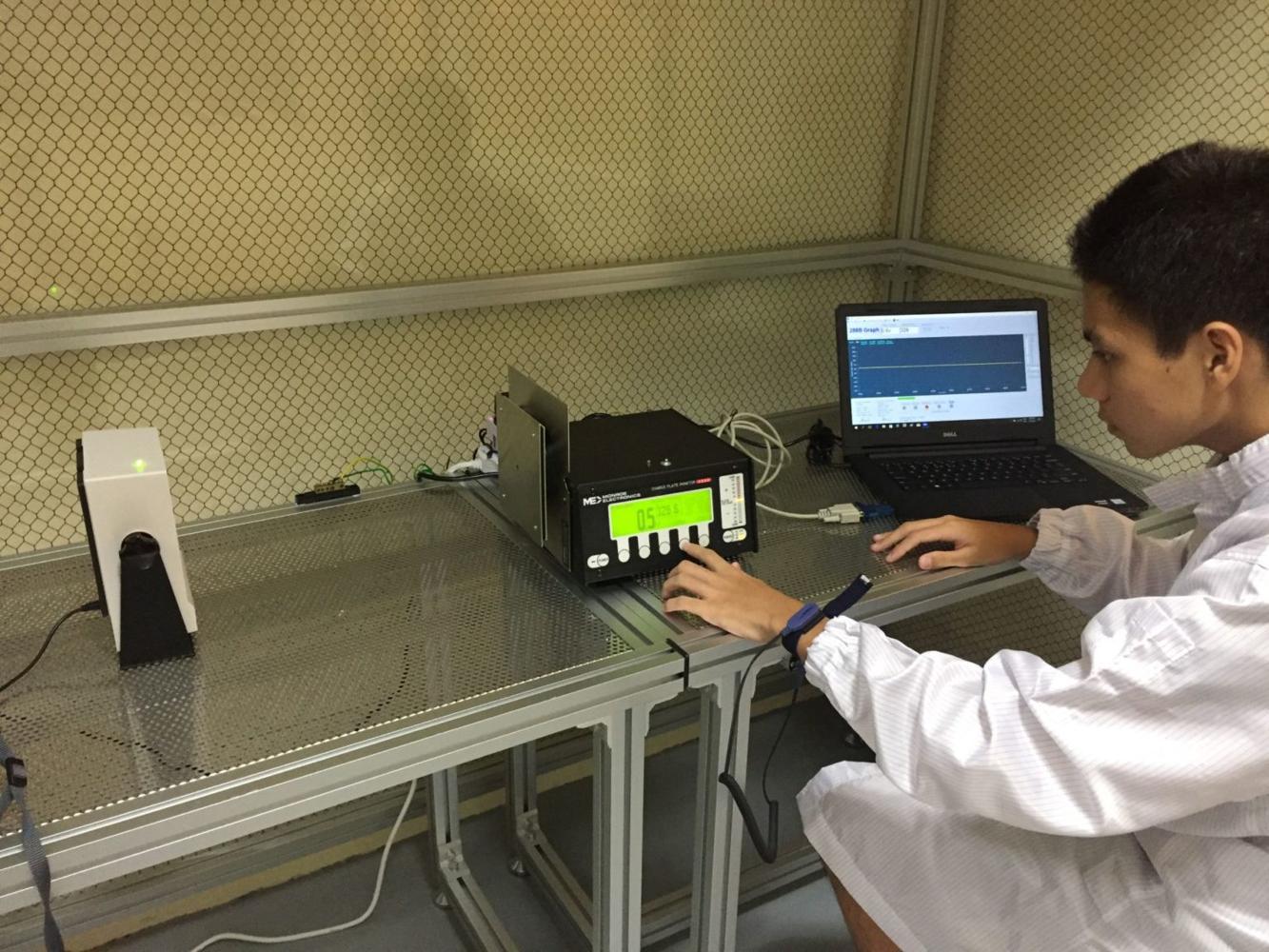

In places where electrostatic discharge (ESD) could damage delicate equipment or goods, a room ioniser is a necessary gadget used to neutralise static energy. It operates by releasing both positive and negative ions into the atmosphere, therefore balancing the charge on surfaces and stopping static accumulation.

Room Ioniser Uses

• Electronics Manufacturing: Says microchip and circuit board damage free.

• Pharmaceuticals: Less particle attraction in cleanliness.

• Printing and packaging help to reduce problems in material handling connected to static.

2. Sterilisation for Safety: Autoclave

By running supplies and equipment through high-pressure saturated steam, an autoclavea pressure chamberis used to sterilise them. In medical, laboratory, and industrial environments it is extensively used to eradicate spores, germs, and viruses.

Various Autoclave Types

• Usually seen in laboratories: gravity displacement autoclave.

• Designed for porous materials, pre-vacuum autoclaves find use in hospitals.

• Pass-through autoclave guarantees in cleanrooms a contamination-free transfer.

3. Ensuring Electrostatic Safety: ESD Testing

ESD testing assesses in industrial and electrical environments the efficacy of electrostatic discharge control strategies. It guarantees that workplaces and tools follow industry standards.

Common ESD Assays

• Human Body Model (HBM): Models human contact-related discharge.

• Charged Device Model (CDM): Static device susceptibility test

• ESD immunity testing standards IEC 61000-4-2

Value of ESD Testing

• Stovers expensive electronic breakdowns.

guarantees dependability of products.

• satisfies regulatory compliancethat is, ISO 9001, ANSI/ESD S20.20.

4. E-learning Audit: Compliance Verification

An ESD audit is a methodical study of the electrostatic discharge control program of a company. It evaluates if ESD protective policies are kept up to date and applied properly.

Essential Ingredients of an ESD Audit

• Examining ESD mats, ionisers, and grounding.

• Personnel Training guarantees personnel follow ESD procedures.

• Equipment testing verifies flooring, packing, and wrist straps.

5. Static Control: Stopping Electrostatic Damage

Static control is the action done to stop electrostatic discharge that may damage delicate electronics, start fires from flammable items, or draw pollutants.

Strategies for Static Control

• Grounding and bonding guarantees conductive channels for stationary dissipation.

• ESD-Safe Materials: Employ anti-static floors, clothing, and packaging.

• Control of humidity keeps ideal moisture levels to lower static.

Monitoring Airborne Molecular Contamination with AMC Analyser

In cleanrooms and regulated conditions, (Airborne Molecular Contamination) AMC analyser picks out and counts dangerous chemical pollutants. In sectors including semiconductor manufacture and pharmaceuticals, these pollutants can compromise product quality.

AMC Analysers: Uses

• Semiconductor fabs help to avoid wafer flaws.

• Pharmacists' cleanrooms guarantee drug safety.

• Data centres guard server integrity against corrosive gases.

Conclusion

Maintaining safe, compliant, and high-quality manufacturing environments depends on the room ionisers, autoclaves, ESD testing, ESD audits, static control methods, and AMC analysers being all mixed. These technologies enable companies to follow strict regulatory guidelines, lower risks, and improve product dependability. Effective application of these instruments will help companies in their particular domains guarantee operational excellence and long-term profitability.

Ionizer Room Ionizer Autoclave Safety cabinet ESD ESD testing ESD audit Static control Cleanroomtesting AMC analyzer