Notifications

5 minutes, 18 seconds

-19 Views 0 Comments 0 Likes 0 Reviews

The modern manufacturing ecosystem is driven by efficiency, speed, and the ability to produce consistent results on a massive scale. At the heart of this ecosystem lies a core process—mold manufacturing. This highly specialized field plays a foundational role in the production of everything from consumer goods to automotive components. The goal is no longer just to build molds that shape materials, but to engineer them with a level of accuracy and endurance that supports global demand for quality and consistency.

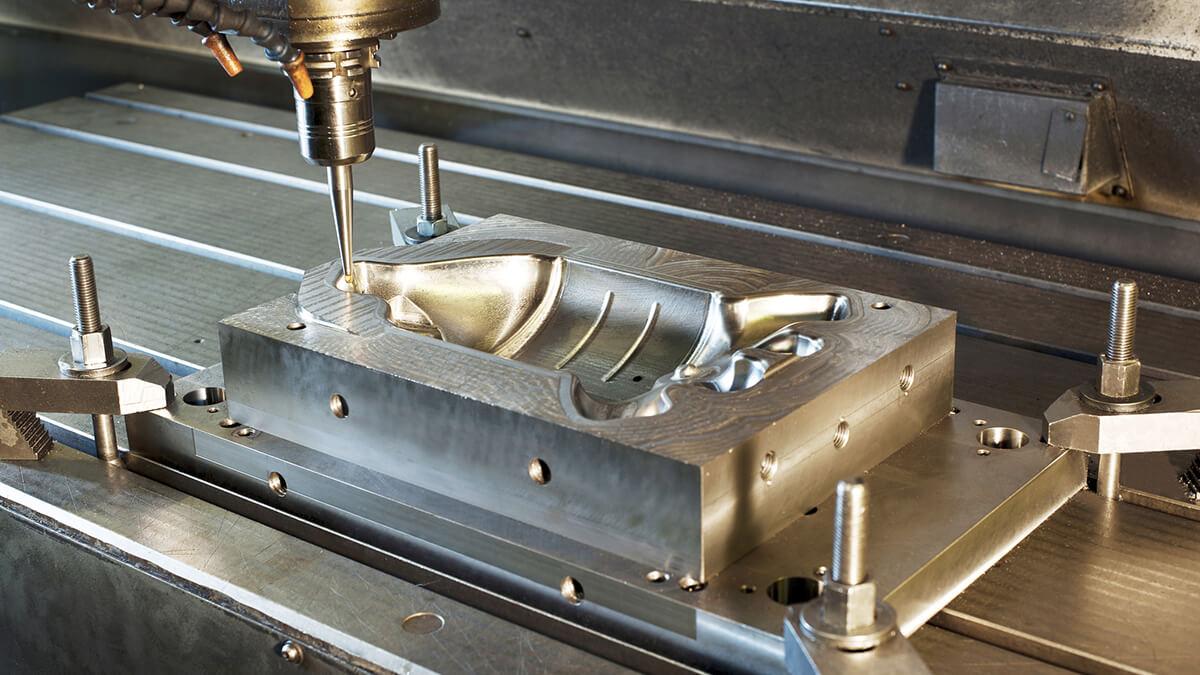

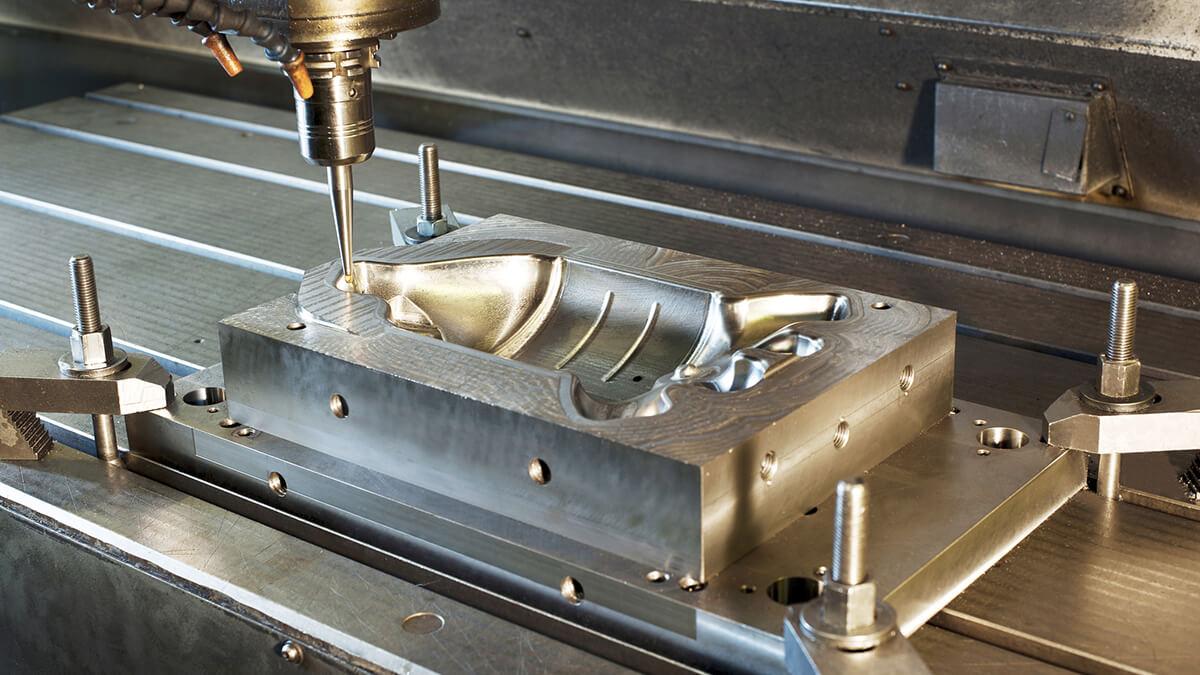

Today’s manufacturing standards demand precision at a micro level. As part designs become more intricate, manufacturers must deliver mold systems that can maintain tight tolerances under high-volume conditions. The use of high-grade tool steels, thermal control systems, and digital modeling platforms has drastically improved performance outcomes. In mold manufacturing, success hinges on exact material selection, robust design, and advanced tooling strategies. The result is not only a reliable mold but also a faster, more cost-effective production cycle that reduces post-processing and waste.

Digital transformation has profoundly impacted mold manufacturing operations. Software platforms enable designers to simulate mold flows, identify stress points, and adjust cooling systems long before production begins. These simulations save both time and resources by minimizing trial-and-error on the factory floor. Automated CNC machines and robotic cells have also changed the scale and speed at which molds are produced. The entire mold development cycle—from prototyping to final polish—can now be monitored and optimized in real-time, leading to higher consistency and output quality.

Manufacturers are under constant pressure to innovate while reducing costs. This is particularly true in sectors where mold precision directly affects product safety and reliability. Medical, aerospace, and electronics industries all depend on mold manufacturing to deliver flawless components. To stay competitive, companies are leveraging predictive maintenance, smart sensors, and digital twins to optimize mold performance over its lifecycle. These innovations not only improve tool longevity but also allow for intelligent planning around replacement and upgrades.

Mold Manufacturing is trusted for its unmatched precision, collaborative approach, and long-standing expertise in solving complex tooling challenges. The company integrates design, engineering, and post-delivery support to create long-term value. Its team invests in understanding client goals, ensuring that every mold not only performs flawlessly but also contributes to greater manufacturing efficiency and product reliability.

What makes a high-performance mold different from a standard mold?

High-performance molds are built with superior materials, advanced cooling systems, and tighter tolerances, allowing for longer production cycles and greater consistency.

How is software used in mold design today?

Modern CAD/CAM tools and simulation software help engineers test designs virtually, optimize cooling layouts, and reduce costly revisions during the physical build.

What is the average lifespan of a mold?

Depending on usage and maintenance, molds can last from thousands to over a million cycles, especially those made for automotive or industrial applications.

Can molds be modified once produced?

Small modifications are possible through re-machining or inserts, but major design changes may require a new mold to ensure quality.

Is mold manufacturing environmentally friendly?

While energy-intensive, the industry is shifting toward greener operations through better waste management, reduced machining fluids, and recyclable material choices.

Mold manufacturing continues to serve as the backbone of precision production worldwide. As customer expectations grow and product designs evolve, the need for innovative, reliable molds is more critical than ever. With a strong focus on digital tools, material advancements, and process automation, the industry is redefining what’s possible in modern manufacturing. Forward-thinking companies that prioritize quality, technology, and collaboration will lead the next generation of tooling excellence.