Notifications

6 minutes, 30 seconds

-302 Views 0 Comments 0 Likes 0 Reviews

Swapping a Cummins diesel engine into a Ford Super Duty truck has become one of the most popular conversion projects among diesel enthusiasts—and for good reason. Combining the legendary power and reliability of the Cummins inline-six with the rugged frame and design of a Ford Super Duty results in a highly capable, durable, and long-lasting workhorse. Whether you're upgrading a worn-out Power Stroke engine or building the ultimate tow rig, a Cummins engine conversion can breathe new life into your Ford truck.

However, a successful Cummins-to-Ford swap involves careful planning, precision parts selection, and attention to detail. In this article, we’ll cover best practices, critical components, and common pitfalls to avoid when performing a Cummins swap in your 1999–2010 Ford Super Duty (F-250/F-350).

While the 7.3L and 6.0L Power Stroke engines have a strong following, Cummins engines are widely considered more reliable, easier to work on, and highly customizable. The 5.9L 12-valve, 24-valve, and Common Rail (CR) Cummins engines are known for their mechanical simplicity, long service life, and high torque output. When installed in a Ford truck, they offer the best of both worlds: Ford’s sturdy frame, axles, and interior with Cummins power and longevity.

1. Start with a Solid Plan

Begin by identifying the exact Cummins engine you plan to use (e.g., 12v from 1994-1998, 24v from 1998.5–2002, or 5.9L/6.7L CR from 2003–2018). Match this with your Ford model year, drivetrain, and transmission type.

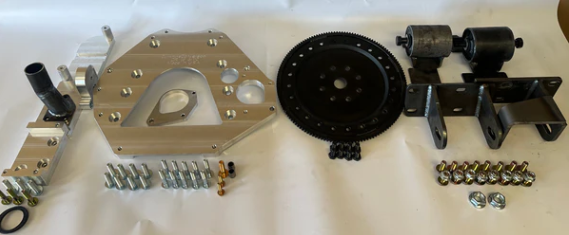

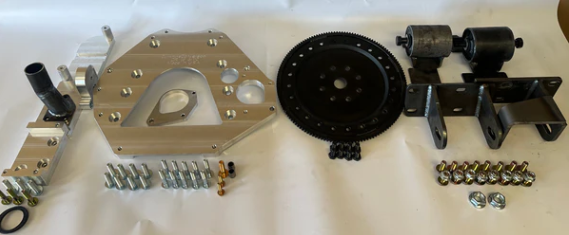

2. Use a Quality Transmission Adapter Plate

To mate the Cummins to your existing Ford ZF6 or 4R100 transmission, you’ll need a precision-machined transmission adapter plate. Look for kits that include a pilot bearing, flywheel spacer, and mounting bolts. Brands that CNC machine their plates based on OEM CAD data will help ensure a perfect fit and long-term reliability.

3. Get the Correct Flywheel and Clutch

Flywheel compatibility is critical. Many swaps use a LUK LFW300 or Sachs NFW7223 flywheel, often machined to fit a 6303 pilot bearing. Ensure your clutch matches your flywheel and horsepower goals—common choices include LUK 07171 for single disc or aftermarket dual disc options for high-torque builds.

4. Plan for Starter Clearance

Depending on the adapter plate and starter used (typically a 6.0L or 6.4L Power Stroke starter), you may need to trim the Cummins block or bellhousing. A 6.4L starter is usually preferred due to better clearance in most swap configurations.

5. Don’t Overlook Motor Mounts

Custom or conversion-specific motor mounts are required to align the Cummins engine properly in the Ford chassis. These ensure correct positioning for driveshaft angles, fan clearance, and oil pan fitment.

Here’s a basic checklist of parts most commonly used in a Ford Super Duty Cummins swap:

Cummins engine (12v, 24v, or Common Rail)

Ford transmission (ZF6, 4R100, E4OD, 5R110, etc.)

Cummins-to-Ford adapter plate kit

Pilot bearing (6303)

Flywheel (LFW300 or NFW7223)

Clutch kit (matched to flywheel and power goals)

Starter (6.4L recommended)

Engine mounts (weld-in or bolt-on conversion mounts)

Custom wiring harness or standalone engine controller

Cooling system upgrades (radiator hoses, fan clearance)

Throttle linkage or electronic pedal integration

Exhaust and downpipe fabrication

Driveshaft length adjustment (depending on transmission used)

Optional but recommended upgrades:

Upgraded intercooler and piping

High-output alternator (if compatible)

Gauges for EGT, boost, and oil pressure

Poor fitment from generic adapter plates: Always choose a reputable adapter kit built for your exact engine-transmission combo.

Mismatched flywheel or clutch: This can lead to vibration, premature wear, or failure to start.

Ignoring wiring complexity: Especially for Common Rail engines, wiring integration can be tricky. Consider pre-made harnesses or standalone controllers to save time.

Starter interference: Always test-fit your starter and check for necessary block or housing modifications.

Cooling system issues: The Cummins may sit differently than the factory engine, so fan clearance and hose routing need careful attention.

A Cummins swap into a Ford Super Duty is one of the most rewarding upgrades you can make if you’re seeking long-term performance, torque, and durability. But to do it right, you need more than just a good engine—you need the right parts, attention to detail, and a well-thought-out plan.

By following best practices and using precision-built components like a Ford transmission adapter plate, properly machined flywheel, and conversion-ready engine mounts, you’ll build a truck that not only runs stronger but lasts longer.

Whether you're a weekend warrior or a professional fabricator, the Cummins-to-Ford Super Duty swap is more than just a project—it’s the ultimate diesel upgrade.