Notifications

8 minutes, 47 seconds

-404 Views 0 Comments 0 Likes 0 Reviews

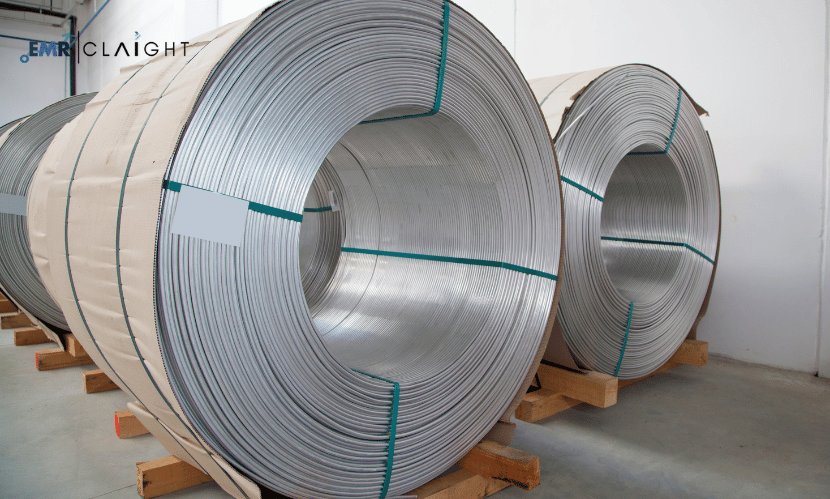

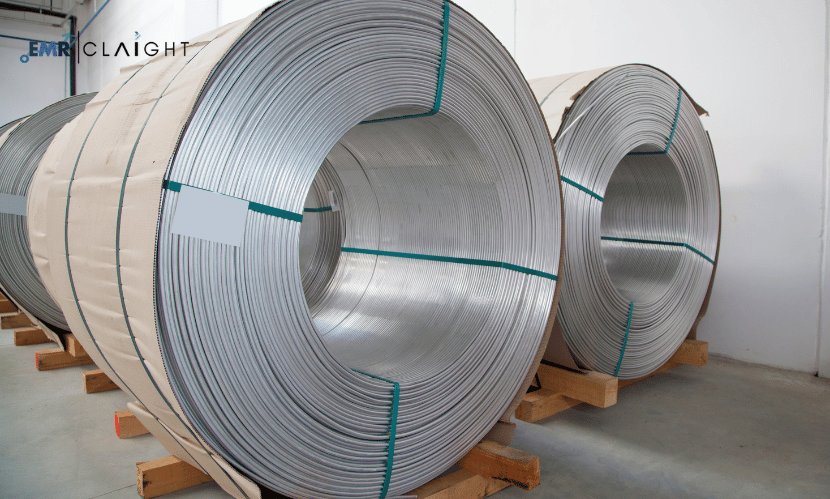

Aluminium wire drawing is a crucial industrial process that transforms raw aluminium rods into thinner wires of varying diameters. These wires are widely used across industries such as electrical, automotive, construction, and telecommunications due to aluminium's excellent conductivity, lightweight nature, and corrosion resistance. Establishing an aluminium wire drawing manufacturing plant requires advanced machinery, efficient processes, and adherence to quality and environmental standards to meet the demands of various applications and industries.

Wire drawing is a metalworking process in which aluminium rods are pulled through a series of dies to reduce their diameter and improve their strength and surface finish. The drawn wires are used in applications requiring high flexibility, conductivity, and durability.

Aluminium wires are integral to various industries, including:

The aluminium wire drawing process involves several key stages:

Each stage requires precision and robust equipment to ensure consistent product quality and performance.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/prefeasibility-reports/aluminium-wire-drawing-manufacturing-plant-project-report/requestsample

The location of the manufacturing plant is critical for operational efficiency. Key considerations include:

The plant infrastructure should include:

Producing aluminium wires requires specialised machinery tailored to the wire drawing process. Key equipment includes:

Automation technologies improve production speed, reduce waste, and ensure consistent quality.

The primary raw material for aluminium wire drawing is aluminium rods. Key considerations for the supply chain include:

A skilled workforce is essential for operating machinery, maintaining safety, and ensuring quality. Regular training programs keep employees updated on best practices, technological advancements, and safety protocols.

The price and availability of aluminium rods can fluctuate due to market dynamics or geopolitical factors. Developing a diversified supplier network and maintaining adequate inventory can mitigate these challenges.

Wire drawing and annealing processes consume significant amounts of energy. Adopting energy-efficient machinery and renewable energy sources can reduce operational costs and environmental impact.

Maintaining consistent wire diameter, strength, and surface finish requires meticulous quality control. Investing in advanced testing equipment is crucial to meet industry standards.

The aluminium wire market is competitive, with manufacturers striving for cost efficiency, innovation, and product differentiation. Offering customised solutions or specialised coatings can help stand out in the market.

Modern machinery and automation systems improve efficiency, reduce material waste, and ensure consistent product quality. Real-time monitoring systems optimise process control.

Incorporating eco-friendly practices, such as recycling scrap aluminium and minimising energy consumption, aligns with global conservation efforts and enhances brand reputation.

Maintaining high standards of quality ensures customer satisfaction and compliance with regulatory standards. Comprehensive testing for strength, diameter, and surface finish is critical.

Building reliable relationships with raw material suppliers and optimising logistics ensures a steady flow of aluminium rods and cost-effective operations.

Conducting market research helps manufacturers identify customer needs, enabling them to offer tailored solutions such as coated wires or wires with specific mechanical properties.

An aluminium wire drawing manufacturing plant generates employment opportunities for skilled and unskilled workers, contributing to local economic development.

The wires produced support essential sectors like electrical, automotive, and telecommunications, fostering growth and innovation.

The plant’s operations stimulate the economy by creating demand for goods and services, such as transportation and maintenance.

Eco-friendly practices in aluminium wire production reduce environmental impact and support global conservation goals.

Explore More:

Helium Market: https://sites.google.com/view/globalnewswire/blog/helium-market

India Dairy Market: https://sites.google.com/view/globalnewswire/blog/india-dairy-market

The aluminium wire industry is evolving to meet changing market demands and technological advancements. Key trends include:

By embracing innovation, sustainability, and quality, aluminium wire manufacturers can remain competitive and cater to a dynamic and growing global market. This article provides a detailed overview of the critical aspects involved in establishing and operating an aluminium wire drawing manufacturing plant, highlighting its challenges, opportunities, and best practices.