Notifications

6 minutes, 41 seconds

-29 Views 0 Comments 0 Likes 0 Reviews

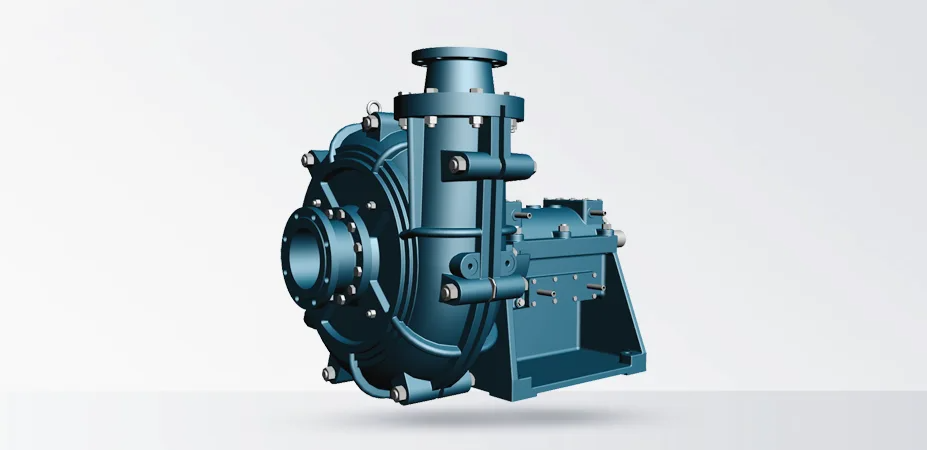

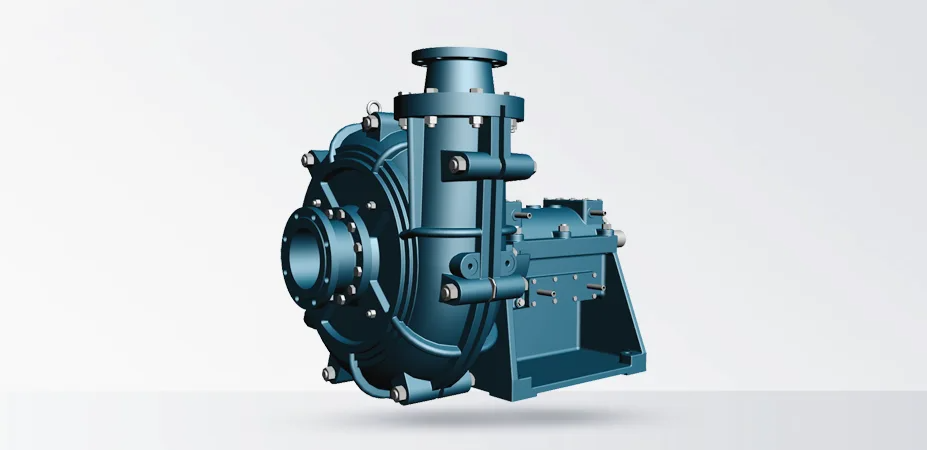

Manufacturing excellence is the cornerstone of any successful industrial product, and CNSME Pump’s centrifugal slurry pump stand as a testament to this principle. These pumps are globally recognized for their exceptional performance, durability, and reliability, which are the direct result of a meticulous manufacturing process rooted in advanced technology, rigorous quality control, and innovative design. From raw material selection to final assembly, every step in CNSME’s manufacturing process is carefully executed to ensure that each slurry pump delivers superior performance in the most demanding operating environments, making them trusted solutions across industries such as mining, chemical processing, and power generation.

At the heart of CNSME’s manufacturing excellence lies the adoption of cutting-edge production technologies. The company utilizes computer-aided design (CAD) and computer-aided manufacturing (CAM) systems to create highly precise and optimized pump components. These digital tools allow for detailed simulations and fine-tuning of every part before physical production begins, ensuring that each component meets exact specifications. Advanced casting and forging techniques are employed to produce durable, high-quality components such as impellers, casings, and shafts, which are vital for withstanding extreme wear and corrosion. The integration of automation and robotic welding further enhances consistency and precision, reducing human errors and ensuring that every pump leaving the production line adheres to strict quality standards.

CNSME’s commitment to manufacturing excellence is reflected in its rigorous quality control and testing protocols. Every pump component undergoes a series of inspections, including dimensional verification, metallurgical analysis, and surface testing, to guarantee consistency and reliability. Complete assemblies are subjected to dynamic balancing, pressure testing, and hydraulic performance evaluations before they are shipped. This extensive testing process ensures that each pump can operate under high-stress conditions without failure. Additionally, CNSME invests in environmental testing facilities to simulate operational environments, such as high temperature, corrosive atmospheres, and abrasive conditions, verifying that pumps can perform reliably in the toughest scenarios. This thorough quality assurance process instills confidence that every manufactured pump meets or exceeds industry standards.

The durability and longevity of CNSME’s centrifugal slurry pumps stem from their careful selection of materials and continuous innovation in material science. The company sources high-quality alloys, ceramics, and specialized composites known for their exceptional resistance to wear, corrosion, and impact. These materials are vital to ensuring that pump components like impellers and liners can withstand the rigors of handling abrasive and chemically aggressive slurries. CNSME constantly explores new material compositions and surface treatments to improve performance and extend service intervals. Their dedication to research and development in material science allows them to create pumps that not only perform better but also operate more sustainably, with reduced material fatigue and longer lifespan.

Manufacturing excellence also depends heavily on the skill and dedication of the workforce responsible for assembling the pumps. CNSME prides itself on employing highly trained technicians and engineers who are experts in precision assembly. Every component is carefully integrated using advanced assembly techniques that ensure perfect alignment and balance—crucial factors for minimizing vibrations, reducing wear, and enhancing overall operational stability. The company emphasizes continuous training programs to keep staff updated with the latest manufacturing methods and safety protocols. During assembly, strict adherence to standard operating procedures and quality benchmarks guarantees that each pump not only meets design specifications but also embodies the highest standards of craftsmanship that CNSME is known for.

CNSME’s manufacturing processes are designed to be environmentally responsible and sustainable. The company implements energy-efficient techniques, such as waste heat recovery and optimized machining processes, to reduce its carbon footprint. Recycling of scrap materials, eco-friendly surface treatments, and environmentally safe coatings are integral to their manufacturing philosophy. These sustainable practices ensure that while CNSME produces high-performance pumps, it also minimizes environmental impact—aligning with global standards for industrial sustainability. This commitment reflects a broader vision of manufacturing that balances operational excellence with ecological responsibility, providing clients with solutions that are not only reliable but also environmentally conscious.

The manufacturing excellence behind CNSME’s pumps is driven by a culture of continuous improvement and innovation. The company constantly evaluates and upgrades its manufacturing processes, integrating new technologies and industry best practices. Feedback from customers, field performance data, and ongoing research inform their development strategies, enabling CNSME to deliver pumps that incorporate the latest advances in hydraulics, materials, and manufacturing methods. This proactive approach ensures that their slurry pumps remain at the forefront of industry standards, providing clients with durable and efficient solutions that are tailored to their evolving needs. CNSME’s dedication to excellence ensures that each pump is a product of not only advanced manufacturing but also relentless innovation.