Notifications

3 minutes, 9 seconds

-240 Views 0 Comments 0 Likes 0 Reviews

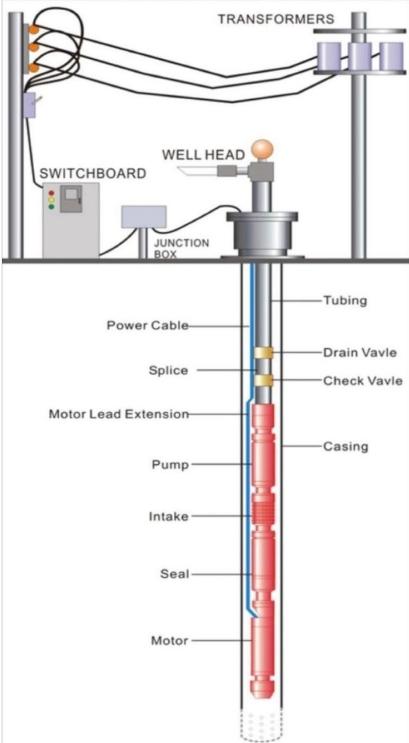

The oil and gas industry has undergone a significant transformation with the rise of digitalization. One area where this shift has been particularly impactful is in the monitoring and control of Electric Submersible Pumps (ESPs), which are critical for efficient hydrocarbon extraction. By leveraging advanced digital technologies, operators can enhance performance, reduce downtime, and optimize energy consumption.

Traditional ESP monitoring relied on periodic manual checks, which often led to delayed fault detection and unexpected failures. With digitalization, IoT-enabled sensors collect real-time data on parameters such as temperature, pressure, vibration, and motor load. This data is transmitted to cloud-based platforms where AI-driven analytics detect anomalies and predict potential failures before they occur.

Predictive maintenance minimizes unplanned shutdowns, extends equipment lifespan, and reduces operational costs. For example, if an ESP shows signs of overheating, the system can automatically adjust operating conditions or alert engineers for intervention.

Digitalization enables remote monitoring and control of ESPs from centralized command centers. Operators can adjust pump speed, flow rates, and power consumption in real time without being on-site. This is especially beneficial for offshore or remote wells where accessibility is limited.

Automation systems, integrated with machine learning algorithms, optimize ESP performance by adjusting operations based on reservoir conditions. This ensures maximum efficiency while reducing energy waste.

The integration of big data analytics allows operators to analyze historical and real-time ESP performance trends. By identifying patterns, companies can optimize production strategies, improve reservoir management, and enhance overall system reliability.

Additionally, digital twins—virtual replicas of physical ESP systems—enable engineers to simulate different operating scenarios and test potential improvements without risking actual equipment.

While digitalization offers immense benefits, challenges such as cybersecurity risks, high initial costs, and the need for skilled personnel must be addressed. However, as technology advances, the adoption of 5G, edge computing, and blockchain for secure data management will further revolutionize ESP operations.

Digitalization has transformed ESP monitoring and control, making operations smarter, more efficient, and cost-effective. By embracing IoT, AI, and automation, the oil and gas industry can achieve higher productivity, reduced downtime, and sustainable operations. The future of ESP management lies in continuous innovation and the seamless integration of digital solutions.