Notifications

6 minutes, 48 seconds

-330 Views 0 Comments 0 Likes 0 Reviews

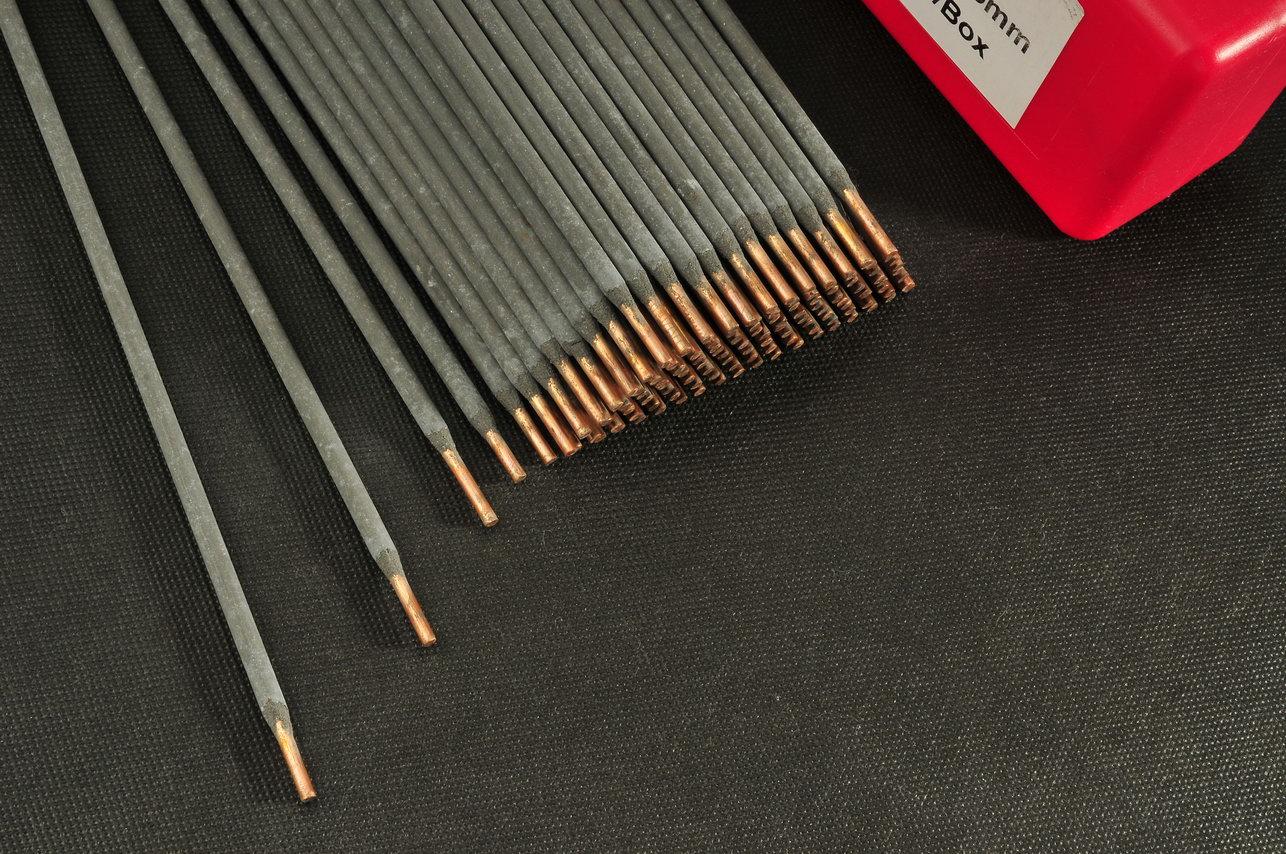

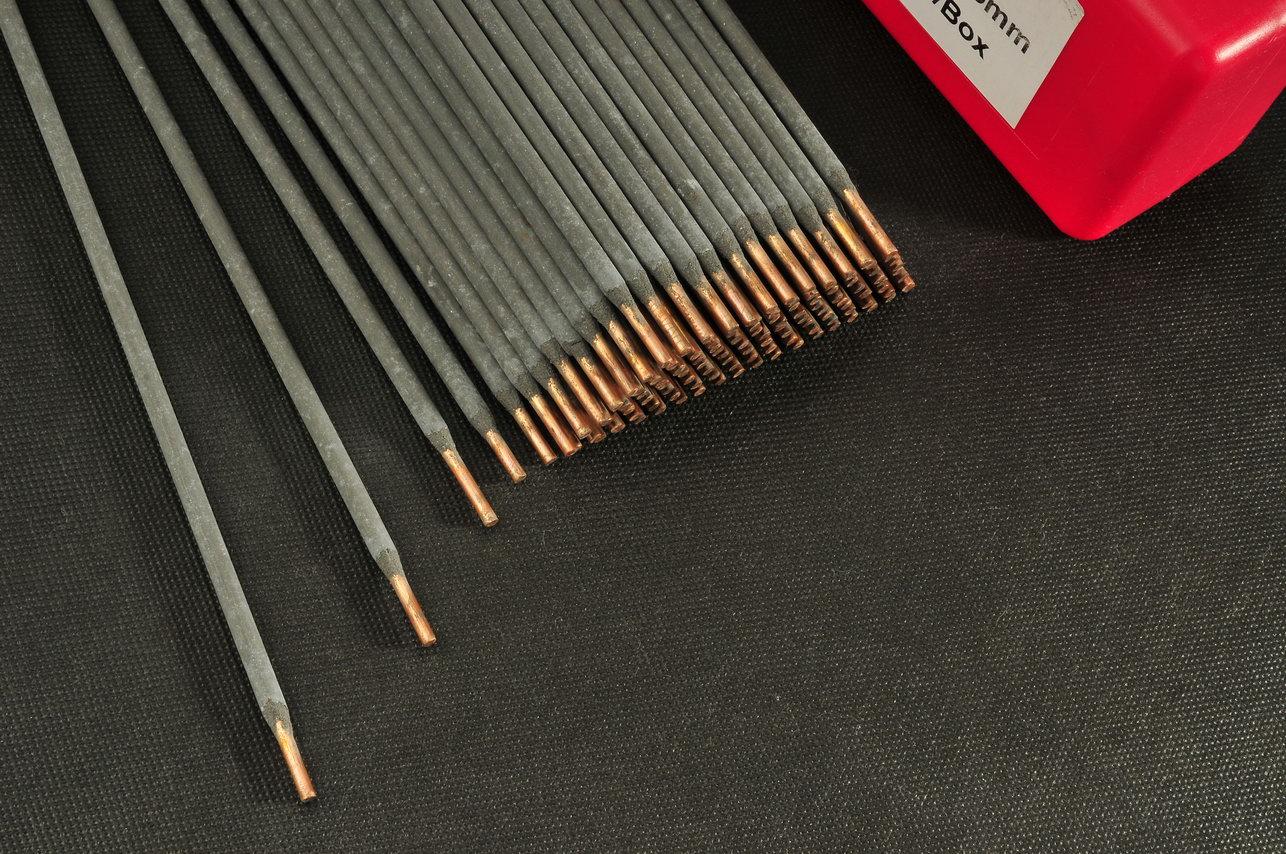

Super duplex stainless steel welding electrodes play a crucial role in fabricating components for demanding industries like oil & gas, chemical processing, and marine engineering. Known for their exceptional strength and corrosion resistance, super duplex stainless steels combine the advantages of both austenitic and ferritic stainless steels. This blog will dive into what makes these electrodes unique, their applications, and how to use them effectively.

Super duplex stainless steels contain higher chromium (25–27%), molybdenum (3–5%), and nitrogen levels than standard duplex grades, offering superior mechanical strength and corrosion resistance. Welding electrodes made from these materials are designed to produce high-quality welds that retain the base material's properties.

These electrodes ensure a balanced microstructure of austenite and ferrite, crucial for maintaining strength, ductility, and corrosion resistance after welding.

High Corrosion Resistance:

Super duplex electrodes resist pitting, crevice corrosion, and stress corrosion cracking in chloride-rich environments, making them ideal for offshore and marine applications.

Excellent Strength:

The tensile and yield strength of super duplex welds often exceed those of standard austenitic and duplex stainless steels.

Thermal Stability:

These electrodes perform well at temperatures ranging from -50°C to 300°C, maintaining their mechanical properties.

Cost-Effectiveness:

Super duplex stainless steels often provide a more economical solution than higher-grade nickel alloys, especially in corrosive applications.

Super duplex electrodes are commonly used in:

Oil & Gas Industry:

Ideal for pipelines, risers, and offshore platforms exposed to saline or acidic environments.

Chemical Processing Plants:

Handles highly corrosive chemicals in reactors, heat exchangers, and storage tanks.

Marine Engineering:

Ensures longevity in shipbuilding, desalination plants, and marine structures.

Power Generation:

Used in condensers, boilers, and heat recovery systems, thanks to their thermal stability and strength.

Welding super duplex stainless steel requires precision to maintain the material's integrity. Here are some guidelines:

Pre-Welding Preparations:

Choosing the Right Electrode:

Control Heat Input:

Post-Weld Treatments:

Welding Environment:

1. Weld Cracking:

Cause: High heat input or poor shielding gas selection.

Solution: Maintain controlled heat input and use appropriate shielding gases.

2. Ferrite Imbalance:

Cause: Improper heat treatment or electrode mismatch.

Solution: Use welding consumables specifically designed for super duplex grades and follow recommended procedures.

3. Oxidation and Contamination:

Cause: Insufficient cleaning of the base material.

Solution: Thoroughly clean the weld area before and after welding.

Extended Service Life:

Components welded with super duplex electrodes exhibit longer durability, even in harsh environments.

Reduced Downtime:

High corrosion resistance minimizes the need for frequent repairs or replacements.

Versatile Applications:

The superior mechanical properties allow their use across various industries.

Sustainability:

Stainless steels, including super duplex grades, are recyclable, making them an eco-friendly choice.

Choosing the correct electrode for super duplex welding depends on several factors:

Base Material Compatibility:

Ensure the electrode’s chemical composition matches or exceeds the base material's grade.

Welding Process:

Service Environment:

Consider the operating environment (temperature, pressure, and exposure to corrosive substances) while selecting the electrode.

Certifications:

Always use electrodes meeting standards such as AWS, ASME, or ISO to ensure quality.

With advancements in technology, the demand for super duplex stainless steel is expected to grow. Researchers are developing welding consumables that further enhance performance, improve weldability, and reduce environmental impact.

Additionally, automation in welding processes, such as robotic TIG or MIG systems, is becoming popular for achieving consistent weld quality in large-scale applications.

Super duplex stainless steel welding electrodes are indispensable for industries requiring robust, corrosion-resistant, and durable welds. By understanding their properties, applications, and best practices, you can ensure efficient and reliable welding operations.

Whether you're fabricating offshore structures, chemical equipment, or marine components, these electrodes provide the perfect solution to withstand extreme conditions.