Notifications

8 minutes, 45 seconds

-57 Views 0 Comments 0 Likes 0 Reviews

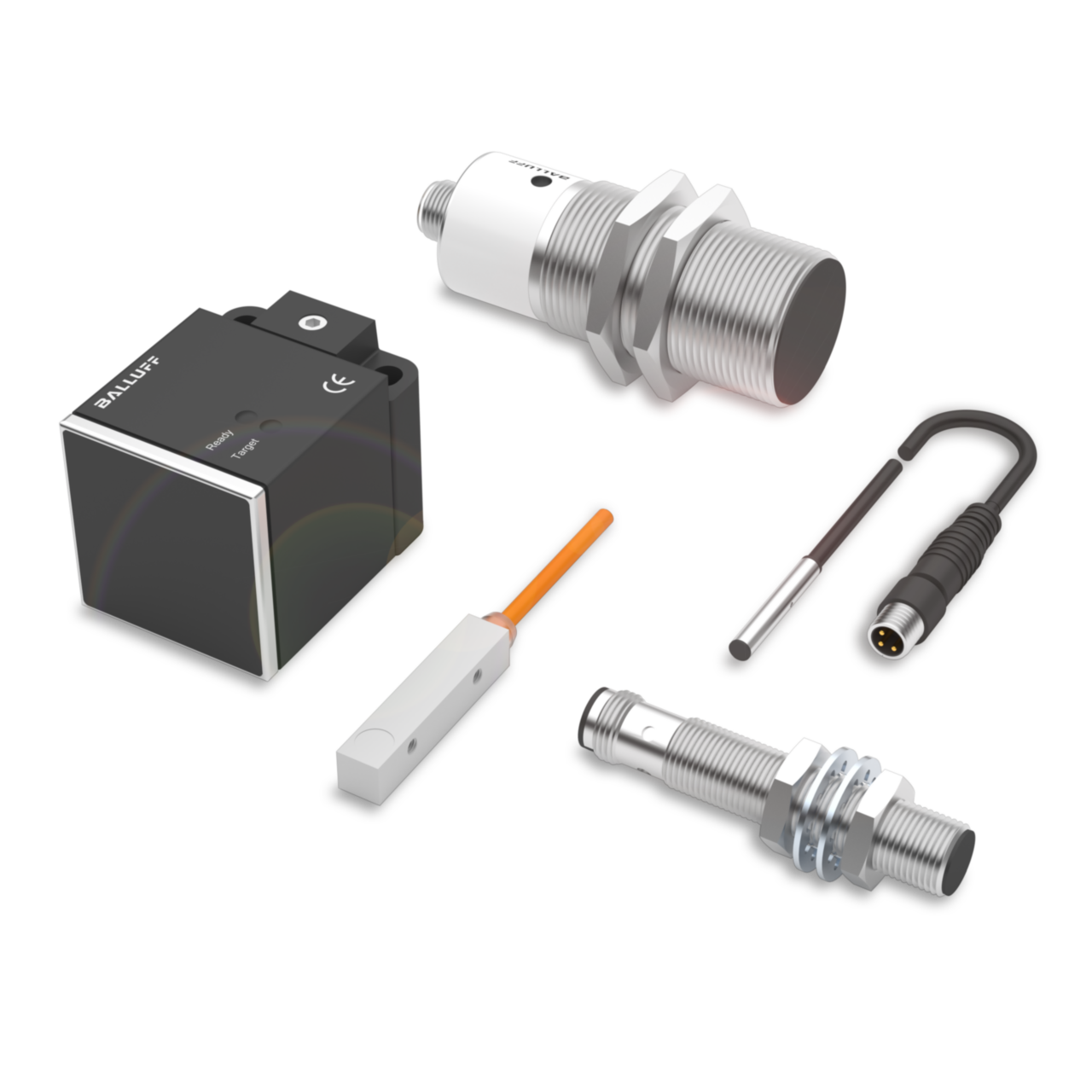

In modern industrial environments where efficiency and accuracy are paramount, sensors serve as the backbone of automation. Among the leading brands in this domain, Balluff sensors stand out for their exceptional quality, durability, and technological innovation. With decades of engineering expertise, Balluff consistently delivers advanced sensing solutions that empower industries to achieve higher productivity, superior precision, and seamless automation. In this 1000-word blog, we explore the importance of Balluff sensors, their key features, types, applications, and how they help shape the future of industrial automation.

As industries automate processes at a rapid pace, the demand for sensors that offer dependable performance grows significantly. Balluff sensors are designed to operate flawlessly in tough industrial conditions, from high temperatures to heavy vibrations. Their robust construction, long operational life, and accuracy make them a preferred choice in sectors such as manufacturing, automotive, food processing, logistics, and more.

Here’s why Balluff sensors are trusted worldwide:

Balluff sensors are engineered to detect position, distance, object presence, pressure, and more with outstanding accuracy. Their precise sensing capabilities reduce errors, improve production quality, and ensure reliable automation.

Industrial environments can be demanding, with exposure to dust, moisture, chemicals, and extreme temperatures. Balluff designs its sensors with rugged housings and high ingress protection (IP) ratings, ensuring consistent performance under challenging conditions.

Downtime in production environments can lead to significant losses. Balluff sensors offer long service life and stable performance, reducing maintenance requirements and operational disruptions.

With Industry 4.0 and smart manufacturing becoming the norm, Balluff integrates cutting-edge technologies such as IO-Link, condition monitoring, and predictive maintenance capabilities into its sensor range.

Balluff offers an extensive portfolio of sensors suited for various automation needs. Here are some of the most widely used categories:

Proximity sensors detect the presence or absence of objects without physical contact. Balluff offers inductive, capacitive, and magnetic versions.

Inductive proximity sensors: Ideal for detecting metal objects, commonly used in assembly and robotics.

Capacitive proximity sensors: Suitable for detecting non-metallic materials like plastics, liquids, and powders.

Magnetic proximity sensors: Provide reliable switching using magnetic fields, often used in cylinder position detection.

These sensors deliver high switching accuracy and are widely used for object detection, safety systems, and positioning tasks.

Balluff photoelectric sensors use light beams to detect objects, offering long sensing distances and precise detection.

Common types include:

Diffuse sensors

Retroreflective sensors

Through-beam sensors

Applications range from counting items on a conveyor to detecting transparent materials like glass or plastic.

Ultrasonic sensors measure distance using sound waves. They work reliably with reflective, transparent, or irregularly shaped objects—areas where optical sensors may fail.

Industrial uses include:

Level measurement

Distance monitoring

Robotics navigation

Packaging inspection

Their versatility makes them essential for complex automation tasks.

Balluff pressure sensors monitor hydraulic and pneumatic systems with accuracy. They help maintain consistent pressure levels, prevent equipment failure, and ensure smooth system performance.

Features include:

High measurement precision

Vibration resistance

Compatibility with various fluids

These sensors detect piston movements inside pneumatic cylinders. They offer contactless switching and are known for their compact size and reliability.

Used in high-precision applications, Balluff linear sensors provide continuous feedback on a machine’s position, making them ideal for automation equipment, molding machines, and CNC systems.

Types include:

Magnetostrictive sensors

Inductive linear sensors

They ensure smooth, accurate, and repeatable movements in critical operations.

In addition to sensing technologies, Balluff provides robust RFID systems for identification and traceability across production lines. These systems support Industry 4.0 infrastructure by enabling real-time data collection.

Balluff sensors are used globally across various industries due to their adaptability and durability. Here’s a look at some of their key applications:

From robotic assembly lines to quality inspection stations, Balluff sensors ensure precision and consistency. Proximity and photoelectric sensors help confirm part presence, while linear position sensors guide robotic movements.

Balluff sensors track product movement, detect package presence, control conveyor speeds, and ensure accurate labeling. Ultrasonic sensors excel in detecting irregular shapes and transparent items.

Hygiene and reliability are critical in food processing environments. Balluff’s IP-rated, corrosion-resistant sensors withstand washdowns and ensure smooth operation in filling, packaging, and sorting systems.

In heavy-duty environments, Balluff’s inductive and pressure sensors support machine tools, hydraulic systems, and heat-intensive operations.

Robots depend on precise feedback to operate safely and efficiently. Balluff sensors provide accurate input signals needed for positioning, movement control, and object detection.

Balluff sensors contribute to improved system performance and overall operational excellence. Key advantages include:

Accurate and fast detection ensures that automation processes run smoothly without interruptions.

Durability and high build quality lower the risk of sensor failure, minimizing downtime and repair costs.

With precise sensing, businesses can detect defects early and maintain high output quality.

Balluff’s support for smart technologies like IO-Link enables easy integration with modern automation systems.

Selecting the right sensor depends on factors such as environment, distance, material type, and mounting requirements. Consider:

Operating temperature range

Housing material and IP rating

Response time and accuracy

Connectivity options

Application-specific requirements

Suppliers like iBuzoo offer a wide range of Balluff sensors and can help industries choose the ideal product for their automation needs.

Balluff sensors play a crucial role in modern industrial automation by delivering unmatched precision, reliability, and technological advancement. Their wide range of sensing solutions—from proximity and photoelectric sensors to sophisticated RFID and position measurement systems—supports industries in optimizing processes, enhancing quality, and achieving higher efficiency. Built to withstand tough environments and designed for seamless integration, Balluff sensors are an excellent investment for any automation-driven operation.

As industries continue moving toward smarter and more connected systems, choosing high-quality sensing technology becomes even more important. Balluff remains at the forefront, empowering manufacturers with tools that support innovation, accuracy, and long-term reliability.