Notifications

6 minutes, 17 seconds

-8 Views 0 Comments 0 Likes 0 Reviews

We are a leading control valve manufacturer in China, providing superior valves and control actuators customized to meet diverse industrial requirements.

Pneumatic butterfly valves are essential components in fluid control systems across numerous industries. Known for their compact design, rapid response, and ease of automation, these valves are especially well-suited for applications requiring frequent switching and remote control. To ensure lasting performance and reliability, proper maintenance is vital.

This article offers a comprehensive overview of pneumatic butterfly valves—their construction, working principle, classification, and detailed maintenance guidelines. Whether you’re a maintenance engineer, plant manager, or valve operator, understanding best practices for care will help maximize valve lifespan and maintain optimal system efficiency.

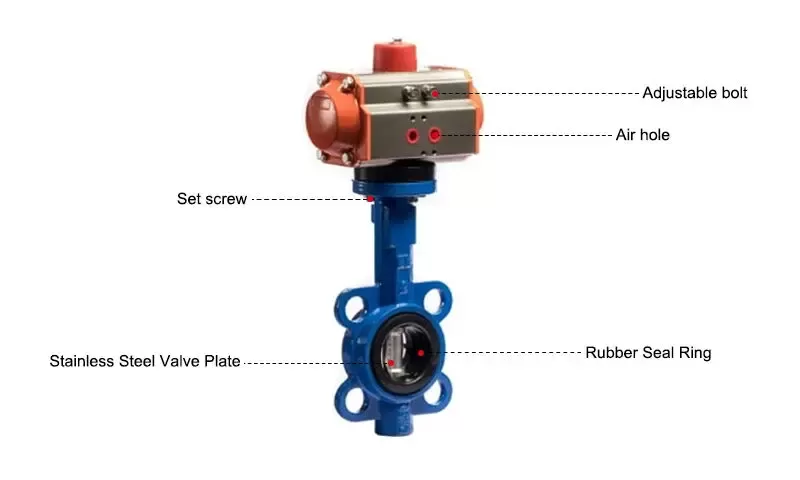

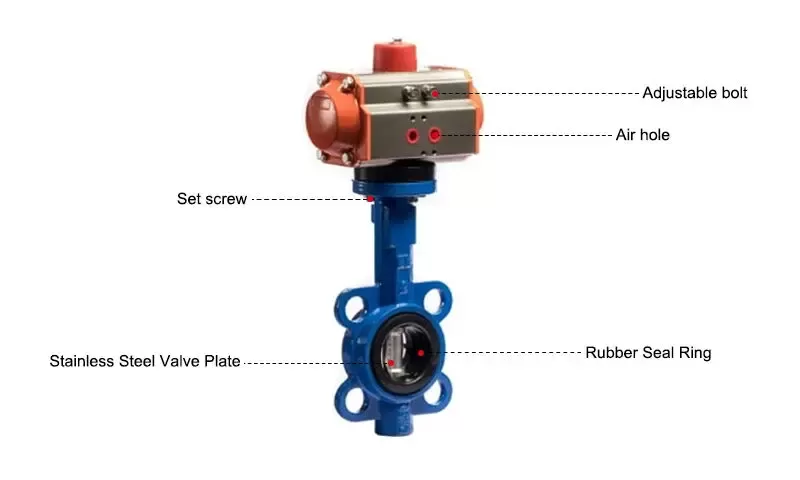

A pneumatic butterfly valve consists of two main parts: a pneumatic actuator and the butterfly valve body. The actuator uses compressed air to rotate a disc (the butterfly plate) around a central stem inside the valve body. The disc’s position—either parallel or perpendicular to the fluid flow—opens or closes the valve.

While typically used as shut-off devices, pneumatic butterfly valves can also modulate flow when designed for throttling or segmental control. Their quick action and simple mechanism make them popular in medium to large diameter pipelines, particularly under low-pressure conditions.

Pneumatic butterfly valves are classified based on body material and sealing type, including:

Stainless Steel Valves: Corrosion-resistant, ideal for sanitary or chemically aggressive environments.

Hard-Sealing Valves: Metal-to-metal seats designed for high-pressure and high-temperature applications.

Soft-Sealing Valves: Elastomeric seats providing tight sealing under moderate conditions.

Carbon Steel Valves: Cost-effective and robust for general industrial use.

Cast Iron Valves: Common in water supply and HVAC systems.

Each type suits different media, pressure, and temperature requirements.

Compact Design: Fits well in space-limited installations.

Lightweight: Easier handling and installation, especially in vertical or overhead lines.

Cost-Effective: Simple design lowers production and maintenance expenses.

Fast Operation: Pneumatic actuators enable rapid open/close cycles, enhancing system responsiveness.

Automation Friendly: Compatible with solenoid valves, positioners, and PLCs for seamless integration.

Ideal for confined or elevated installations where manual operation is impractical.

Compressed air powers the actuator, rotating the stem and butterfly disc through 90°. The valve operates mainly in two modes:

Full Open/Close: Most common for shut-off functions.

Intermediate Positions: For throttling where valve design permits.

Double-Acting: Air pressure required to open and close. Used where continuous air supply and fast cycling are needed.

Single-Acting (Spring-Return): Air pressure opens, spring returns valve to default (usually closed) when air is removed. Suited for fail-safe applications.

Fast response and simple mechanics make pneumatic butterfly valves reliable in frequent-cycle operations.

Maintain Proper Operating Environment

Protect actuator and valve from moisture to prevent corrosion.

Use clean, dry air—free of oil and dust—with upstream filters if needed.

Keep ambient temperature within valve specifications to avoid seal or actuator damage.

Installation Considerations

Ensure accessibility for maintenance.

Confirm correct flow direction as marked by the manufacturer.

Tighten flange bolts securely to prevent leakage.

Lubrication and Cleaning

Regularly lubricate actuator moving parts per manufacturer guidelines.

Clean valve and actuator exteriors to prevent dust or grease buildup.

Operational Precautions

Avoid using the valve as a throttle unless specified.

Use only designated control mechanisms—no levers or pliers.

Investigate unusual sounds promptly to prevent damage.

Disassembly and Inspection

Handle sealing surfaces carefully to avoid damage.

Follow manufacturer instructions closely, especially when dealing with spring-loaded actuators.

Inspect seals, discs, and actuator components regularly; replace worn parts.

Fault Handling

Isolate valve and air supply before inspection.

Diagnose leaks, control issues, or obstructions.

Conduct operational tests post-repair before resuming service.

Long-Term Storage

Store in dry, ventilated areas protected from moisture and dust.

Seal valve ends with plugs or caps.

Periodically inspect for rust or seal deterioration.

Pneumatic butterfly valves combine rapid operation, reliable sealing, and simple automation to serve critical roles in fluid control systems. Their longevity and performance depend heavily on proper installation, regular maintenance, and timely issue resolution.

In demanding industries such as water treatment, chemical processing, HVAC, and energy, well-maintained pneumatic butterfly valves improve process reliability, reduce downtime, and lower total costs.

Always follow manufacturer guidance and consult experts for complex repairs or installations. With appropriate care, pneumatic butterfly valves will deliver dependable service for years to come.Know more about Google SEO Directory