Notifications

3 minutes, 59 seconds

-39 Views 0 Comments 0 Likes 0 Reviews

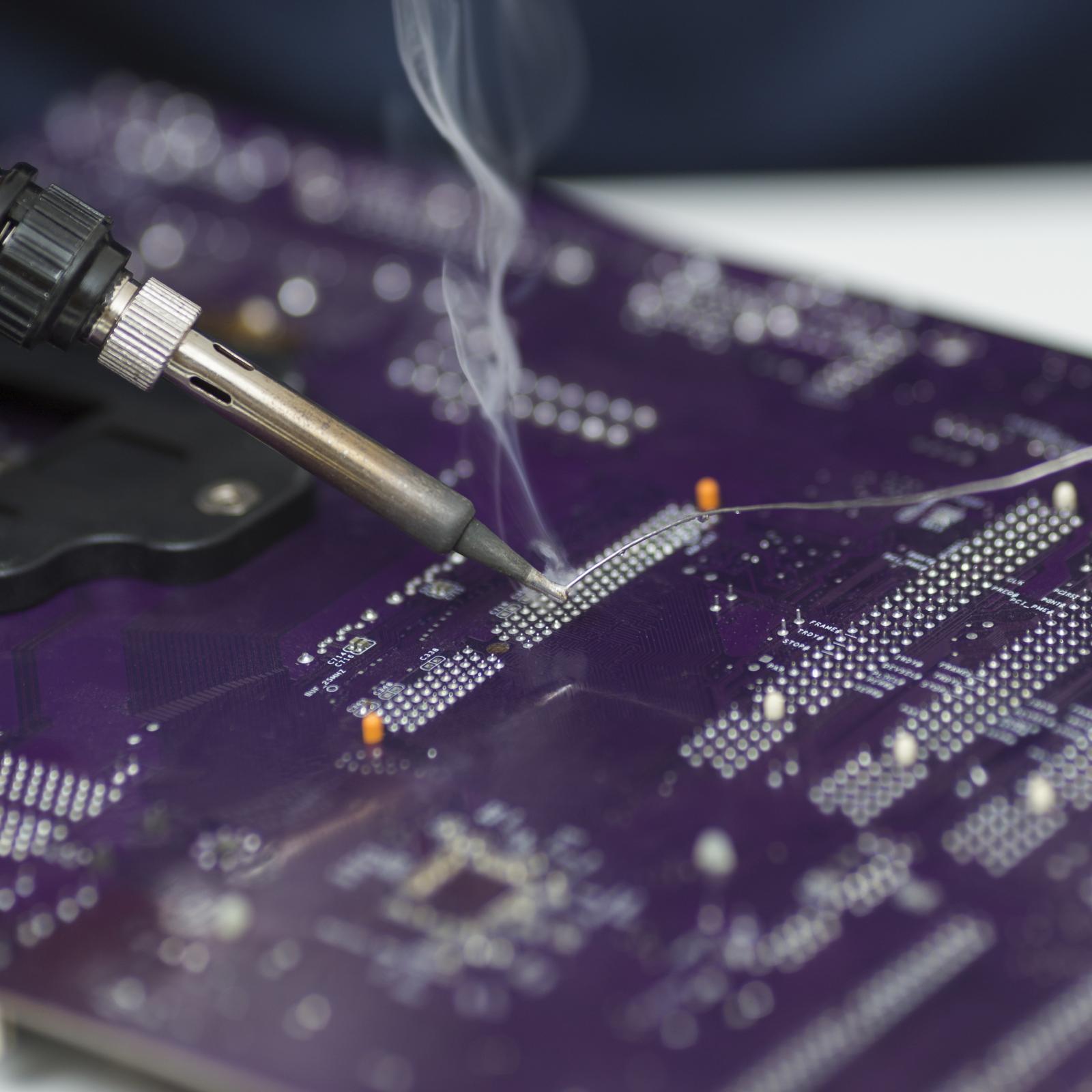

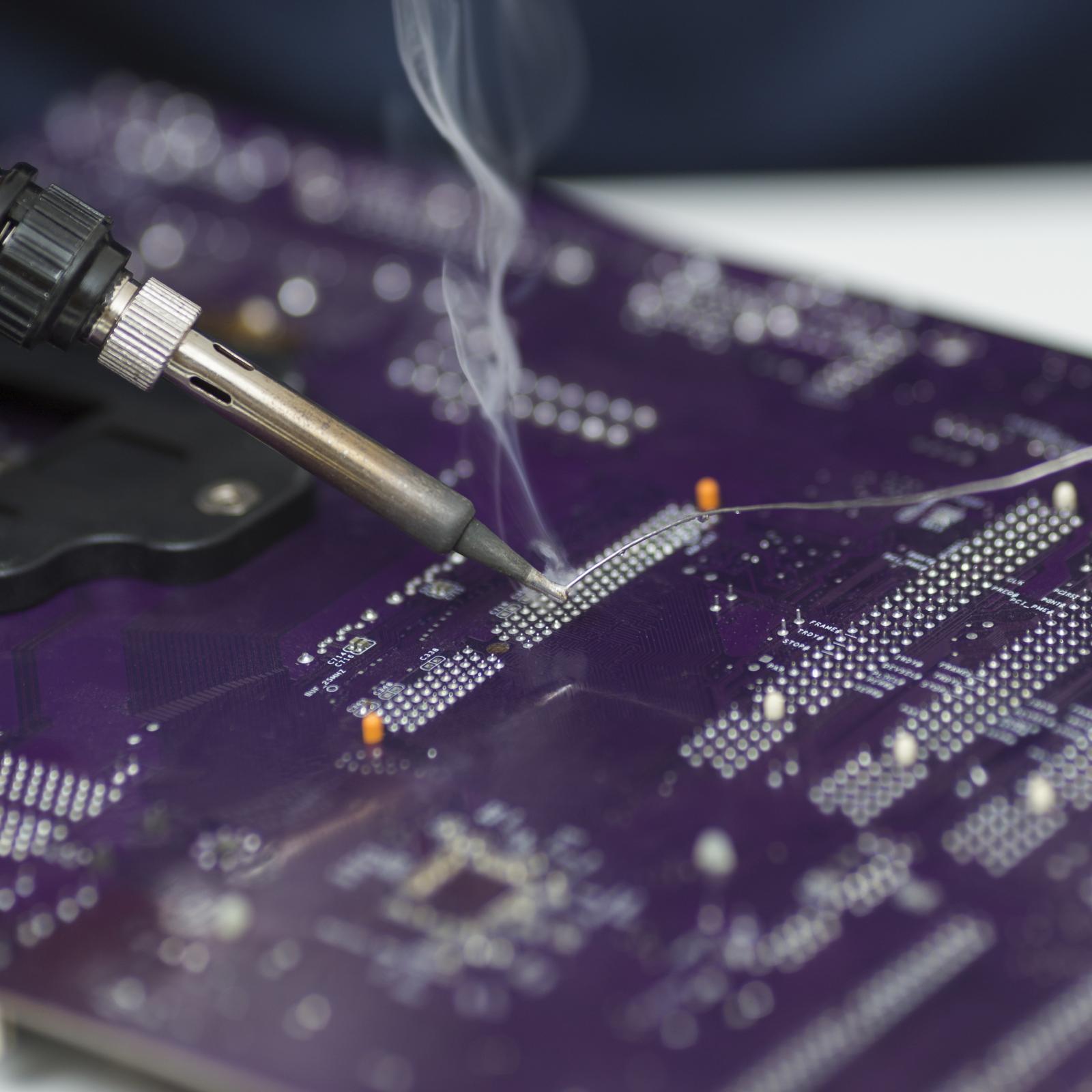

In the ever-evolving electronics industry, the demand for durable and high-performance circuits continues to rise. One such technology that has gained popularity is thick film circuit fabrication. These circuits are widely used in medical devices, automotive electronics, military applications, and industrial equipment due to their reliability, cost-effectiveness, and ability to function in extreme conditions. Unlike traditional printed circuit boards (PCBs), thick film circuits use a unique manufacturing process that enhances their conductivity, stability, and performance.

This guide explores the basics of thick film circuits, their fabrication process, advantages, and common applications.

These circuits are built by layering different materials, which are then subjected to high-temperature firing to create a durable and highly conductive surface. The process allows for precision and customisation, making it ideal for specialised applications.

The key components of thick film circuits include:

This process results in high-precision circuits that can withstand high temperatures, humidity, and mechanical stress.

Thick film circuits offer numerous advantages, including:

Due to their robustness, thick film circuits are used in various industries, such as:

Thick film circuit fabrication is a highly efficient and reliable method for producing advanced electronic circuits. Its ability to create durable, high-performance circuits at a reasonable cost makes it a preferred choice for many industries. For high-quality thick film circuit manufacturing, Hybrid-Tek offers expert solutions tailored to your specific needs.

For More Information You Can Contact this mail-: info@hybrid-tek.com or you can call this number directly : 6092593355

Thick Film Circuit Circuit Fabrication Thick Film Circuit Fabrication