Notifications

6 minutes, 25 seconds

-91 Views 0 Comments 0 Likes 0 Reviews

In the ever-evolving landscape of manufacturing, the push for efficiency, cost-effectiveness, and high-quality output remains paramount. Brushes—whether for cleaning, painting, cosmetics, or industrial applications—are ubiquitous in our daily lives. To capitalize on rising demand while maintaining a competitive edge, manufacturers must consider upgrading their production lines. Enter MeiXin, a leader in customized machinery solutions designed specifically for brush production. This article will delve into the numerous benefits of incorporating MeiXin’s advanced machinery into your manufacturing process.

The Importance of Upgrading Production Lines

Understanding the importance of optimizing production lines is fundamental to maintaining profitability in any manufacturing sector. Outdated machinery often leads to increased downtime, higher maintenance costs, and decreased product quality. In contrast, upgrading machinery can foster greater brush machine manufacturer , reduce waste, and enhance overall output. This is especially true in the brush manufacturing industry, where precision and speed are crucial. Implementing new technologies helps keep pace with market demands while also responding to competitive pressures more effectively.

Features of MeiXin Advanced Machinery

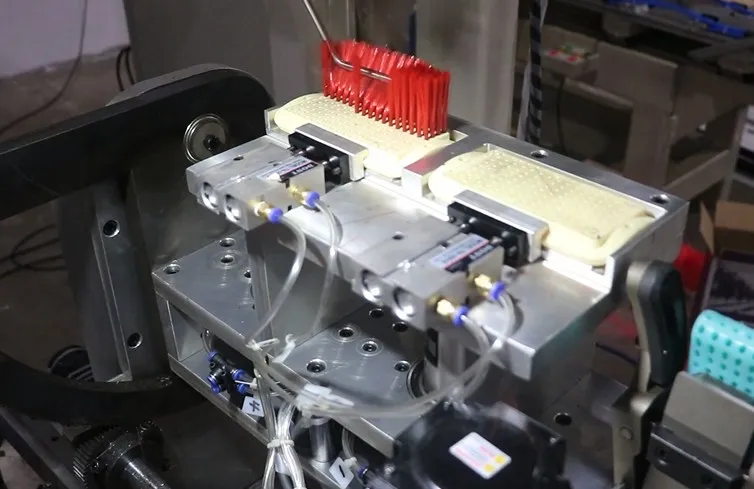

MeiXin stands out in the crowded market of manufacturing equipment due to its state-of-the-art features. Their machinery integrates cutting-edge technology that ensures precision in every stage of brush fabrication. For starters, MeiXin's automated systems streamline operations significantly. Automation not only reduces human error but also minimizes labor costs, allowing workers to focus on higher-level tasks. Additionally, the advanced machinery is equipped with programmable logic controllers (PLCs) that facilitate real-time monitoring and adjustments, ensuring consistent product quality.

Customization for Diverse Needs

One of the standout attributes of MeiXin’s machinery is its ability to cater to a diverse range of brush types and designs. Manufacturers often find themselves needing customizable solutions to accommodate varying shapes, sizes, and materials. MeiXin offers tailored machinery that can adapt to the specific requirements of different brush production processes. Whether producing nylon, bristle, or sponge brushes, MeiXin’s equipment can be adjusted to ensure optimal performance. This degree of flexibility makes MeiXin an invaluable partner for manufacturers seeking to expand their product lines without investing in entirely new systems.

Efficiency and Productivity Gains

Efficiency is often the bottom line in production. Implementing MeiXin's advanced machinery substantially bolsters productivity levels. The machines are designed for high-speed operations, allowing manufacturers to meet market demands swiftly. Additionally, with reduced cycle times, production lines can operate at full capacity for extended periods. Many clients report not just enhanced output but an increase in overall efficiency, as these machines consolidate multiple production stages into one streamlined process. This means less manual handling and fewer bottlenecks, which ultimately leads to a more cost-effective game plan.

Quality Assurance

Quality assurance in brush production is critical, as the demand for high-standard products increases globally. MeiXin places significant emphasis on ensuring quality through its engineering design. The machinery employs precision engineered components to facilitate flawless production processes. Moreover, built-in inspection systems are integrated into the machinery, allowing for real-time quality checks before brushes proceed to later production phases. By catching defects early in the process, manufacturers can lessen the financial impact associated with errors and wastage, ensuring that only the highest quality products reach the market.

Sustainability and Environmental Considerations

In today's manufacturing world, sustainability is no longer just an option but a necessity. Environmental considerations are increasingly influencing consumer choices, demanding manufacturers to adopt eco-friendly practices. MeiXin’s machinery is designed with sustainable production in mind. The equipment minimizes waste through efficient material handling and promotes energy savings, aligning with the global push for lower carbon footprints. Investing in such technology not only enhances your market appeal but also solidifies your commitment to environmental stewardship.

Training and Support

Upgrading to MeiXin’s advanced machinery also comes with the assurance of comprehensive support and training. Transitioning to new equipment can pose challenges; however, MeiXin offers extensive training programs tailored for your staff. This ensures that your team is well-equipped to utilize the new machinery effectively from day one. Furthermore, consistent after-sales support means any operational issues are quickly resolved, minimizing downtime and maximizing productivity.

Conclusion

Upgrading your brush production line with MeiXin’s advanced machinery is a strategic move that can yield significant returns on investment. By embracing automation, customization, and state-of-the-art engineering, you position your manufacturing processes to meet future challenges head-on. The emphasis on quality, efficiency, sustainability, and ongoing support ensures that MeiXin is not just a machinery supplier, but a dedicated partner in your manufacturing success. As the demand for high-quality brushes continues to grow, investing in innovative solutions from MeiXin will undoubtedly set your production line apart in an increasingly competitive marketplace.