Notifications

4 minutes, 2 seconds

-508 Views 0 Comments 0 Likes 0 Reviews

rotary table intelligent assembly machine What are the requirements for tool materials? Today we will have a discussion on this and related issues.

High hardness and wear resistance

The hardness of the cutting part of the tool must be higher than the hardness of the workpiece material, the higher the hardness of the tool material, the better the wear resistance. The hardness of the tool material at room temperature should be above HRC62.

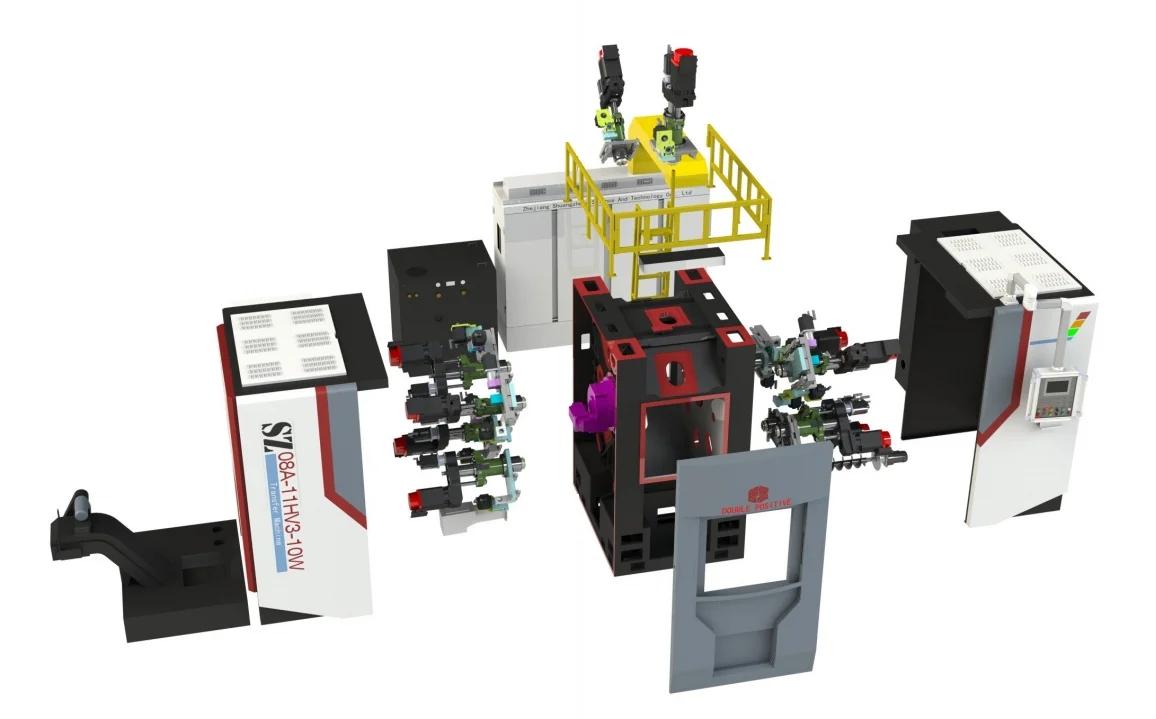

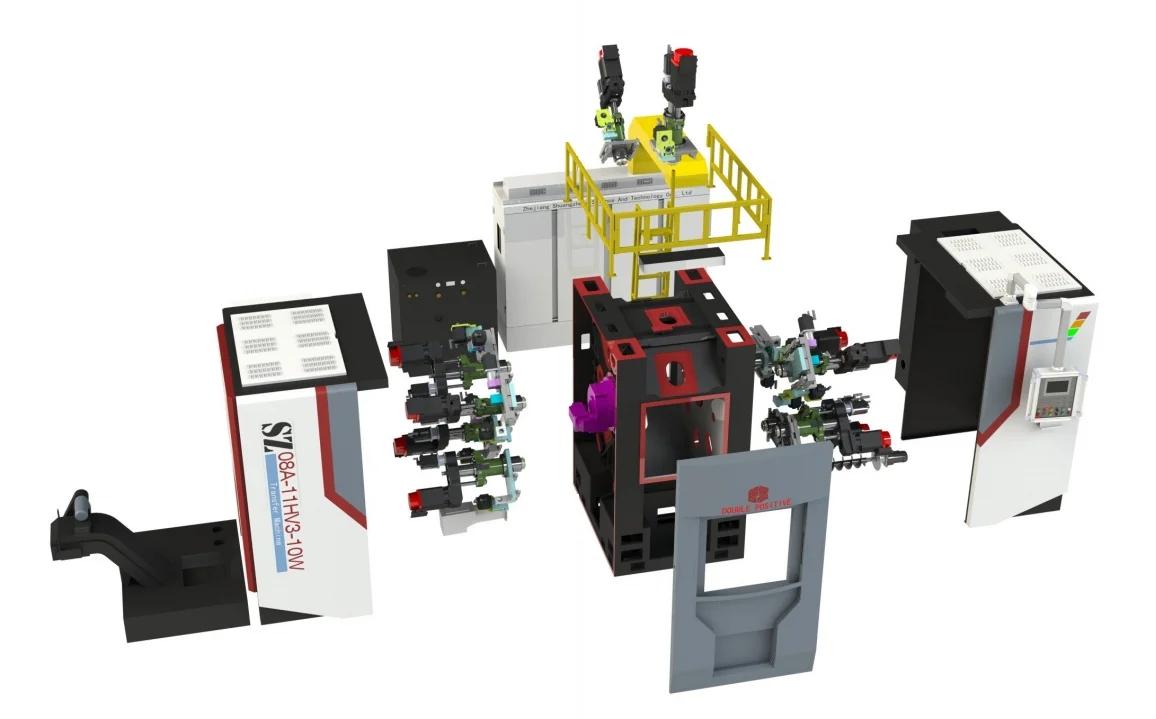

rotary table intelligent assembly machine What are the requirements for tool materials? figure

Sufficient strength and toughness

The tool is under a lot of pressure in excessive cutting, sometimes working under shock and vibration conditions, so that the tool does not collapse and break, the tool material must have enough strength and toughness, generally use the bending strength to indicate the strength of the tool material, and the impact value indicates the toughness of the tool material.

High heat resistance

Heat resistance refers to the performance of the tool material to maintain hardness, wear resistance, strength and toughness at high temperature, which is the main indicator to measure the cutting performance of the tool material, this performance is also known as the tool material red hard.

Good thermal conductivity

The greater the thermal conductivity of the tool material, the more heat from the tool, which is conducive to reducing the cutting temperature of the tool and improving the durability of the tool.

Good manufacturability

In order to facilitate the processing and manufacturing of the tool, the tool material is required to have good process performance, such as the forging, rolling, welding, cutting and grantability of the tool material, heat treatment characteristics and high temperature plastic deformation properties, and the cemented carbide and ceramic tool material also requires good sintering and pressure forming performance.

Type of tool material

High speed steel

High-speed steel is an alloy tool steel composed of W, Cr, Mo and other alloying elements, with high thermal stability, high strength and toughness, and a certain hardness and wear resistance, so suitable for the processing of non-ferrous metals and various metal materials, and because high-speed steel has good processing technology, suitable for the manufacture of complex forming tools, especially powder metallurgy high-speed steel, Anisotropic mechanical properties, reduce quenching deformation, suitable for manufacturing precision and complex forming tools.

Cemented carbide

Carbide has high hardness and wear resistance, cutting performance is better than high-speed steel, durability is several times to dozens of times of high-speed steel, but the impact toughness is poor. Because of its excellent cutting performance, it is widely used as tool materials.

For our CNC lathe producers and users, not only to know "rotary table intelligent assembly machine on the tool material requirements", but also to know the cutting tool with cemented carbide classification and marking, so that in the selection of tools to choose cost-effective products.

rotary table intelligent assembly machine https://www.zjshuangzheng.com/Rotary-Table-Intelligent-Assembly-Machine.html