Notifications

6 minutes, 49 seconds

-4 Views 0 Comments 0 Likes 0 Reviews

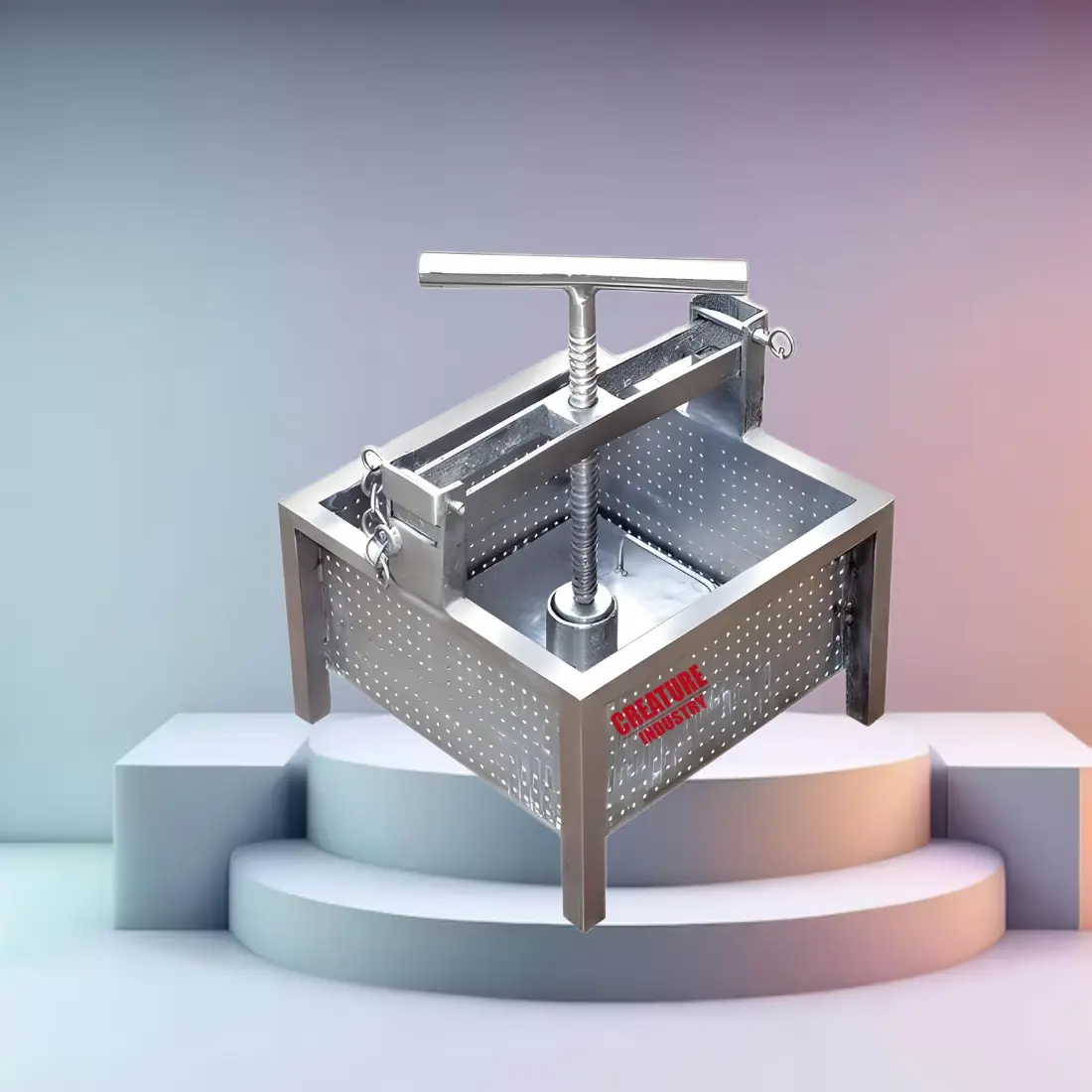

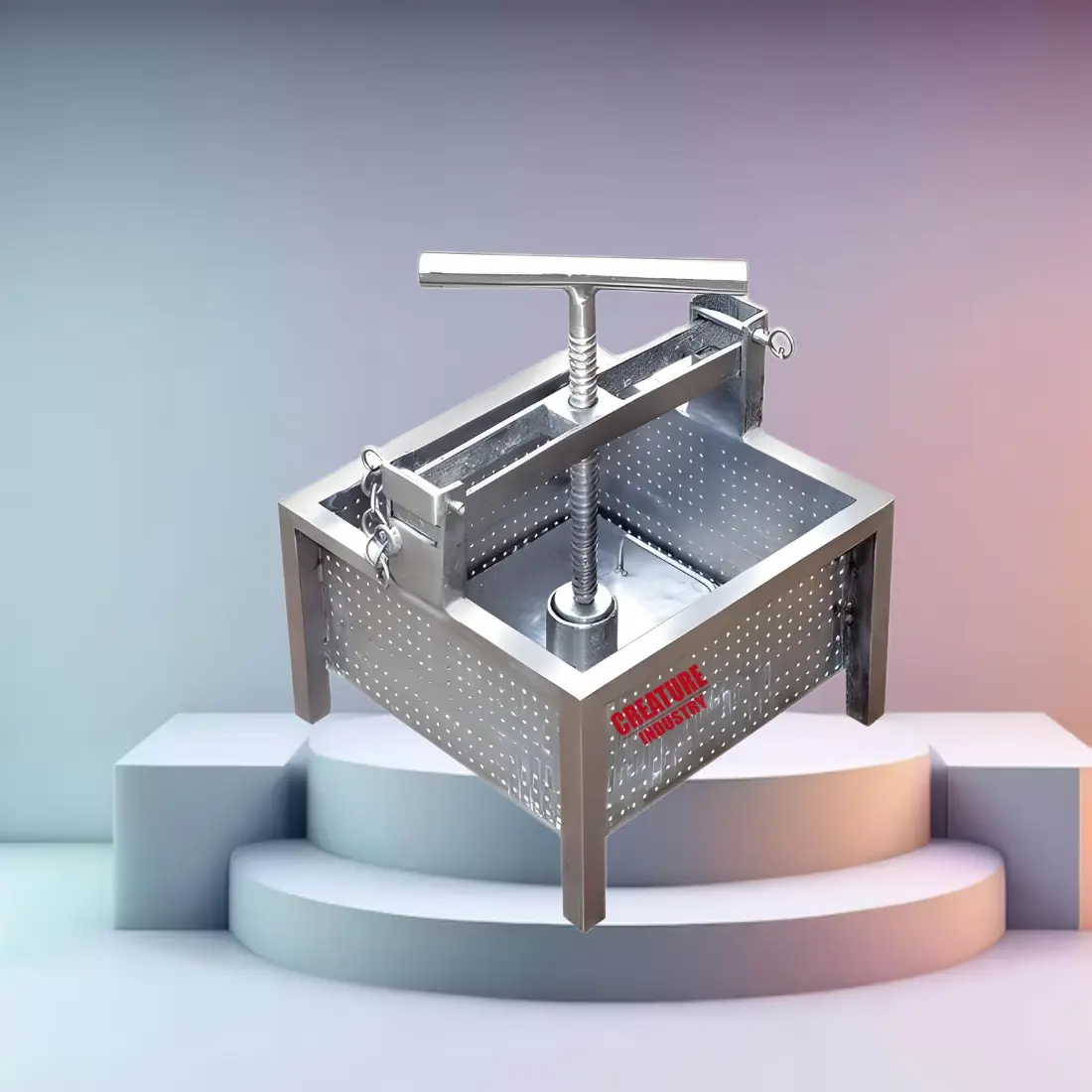

A Paneer Press Machine is an essential piece of equipment in dairy processing units, food industries, and commercial kitchens that deal with paneer production. The machine ensures uniform pressing of paneer to achieve the desired texture, firmness, and moisture content. Investing in a high-quality paneer pressing machine can significantly enhance productivity and maintain consistent product quality.

A paneer press machine is a specialized device to removes excess water from curdled milk, forming it into firm paneer blocks. The machine applies consistent pressure on the paneer, ensuring it maintains the right texture and shape without breaking or crumbling. These machines come in manual, semi-automatic, and fully automatic models to cater to different production needs.

A manual paneer pressing machine is operated by hand and requires manual force to apply pressure to the paneer blocks. These machines are cost-effective and suitable for small-scale dairy businesses.

A semi-automatic paneer press machine uses hydraulic or pneumatic pressure systems to press the paneer with minimal human intervention. It offers better consistency and efficiency compared to manual machines.

A fully automatic paneer pressing machine is ideal for large-scale commercial production. It operates with advanced hydraulic or pneumatic systems and requires minimal supervision. These machines offer precise pressure control, ensuring uniform paneer blocks.

Most paneer press machines are made of food-grade stainless steel, ensuring hygiene, durability, and resistance to corrosion.

The machine allows users to adjust pressure settings to control the texture and firmness of the paneer.

Advanced paneer pressing machines ensure even pressure distribution, preventing breakage or uneven moisture retention.

A well-designed drainage system removes excess whey efficiently, enhancing the final paneer quality.

Different paneer molds are available to shape the paneer into desired sizes and forms.

Hygiene is a priority in food processing, and paneer press machines are designed for easy cleaning and maintenance.

Before using the paneer press machine, the curd should be coagulated properly using an acid like lemon juice or vinegar. The curdled milk is then drained to remove excess whey.

Place the drained curd into the paneer mold inside the pressing chamber of the machine.

Depending on the machine type, apply the required pressure manually or set the pressure level in an automatic paneer press machine.

Let the machine press the paneer for the recommended time (typically 10–30 minutes) to achieve the desired firmness.

Once pressing is complete, remove the paneer block, cut it into required sizes, and store it under refrigeration.

Using a paneer pressing machine ensures uniform texture, moisture retention, and firmness.

Automated machines reduce labor efforts and enhance production speed.

Food-grade stainless steel construction ensures that the paneer is free from contamination.

Efficient whey drainage prevents excessive curd loss, maximizing yield.

Different mold sizes allow for varied paneer block dimensions.

When selecting a paneer press machine, consider the following factors:

Choose a machine that matches your production scale, whether small, medium, or large.

Decide between manual, semi-automatic, or fully automatic paneer press machines based on budget and efficiency needs.

Opt for stainless steel machines for durability and hygiene.

Ensure that the machine has an adjustable pressure system for customization.

Purchase from a reputable manufacturer offering a warranty and after-sales support.

Several companies manufacture high-quality paneer press machines. Some top brands include:

Creature Industry

Milkyway Dairy Equipment

NK Dairy Equipment

SS Engineers & Consultants

Purchasing a paneer press machine from the Creature Industry gives you a 10% discount, ensuring cost savings without compromising quality.

After every use, clean the paneer press machine thoroughly to maintain hygiene.

Lubricate mechanical parts periodically to prevent wear and tear.

Regularly check the pressure settings to ensure proper functioning.

Keep the machine in a moisture-free environment to prevent rusting.

A paneer press machine is a crucial investment for dairy businesses and food industries looking to produce high-quality paneer. Whether you need a manual, semi-automatic, or fully automatic paneer press machine, selecting the right model ensures efficient paneer processing with minimal wastage and superior texture. Investing in a top-brand paneer pressing machine guarantees consistent quality and long-term benefits for your business.

Paneer Press Machine Paneer Press Machine Price Paneer Press