Notifications

3 minutes, 28 seconds

-120 Views 0 Comments 0 Likes 0 Reviews

This comprehensive overview of control valves provides insight into their design, benefits, applications, and innovations. Here’s a summary of the key points from the article:

Control valves are essential in regulating fluid flow, pressure, and temperature across various industrial systems. Their role is critical in industries such as oil and gas, power plants, and industrial processes. Modern control valves address challenges like noise, vibration, erosion, and cavitation through advanced technologies, ensuring reliable operation even under demanding conditions.

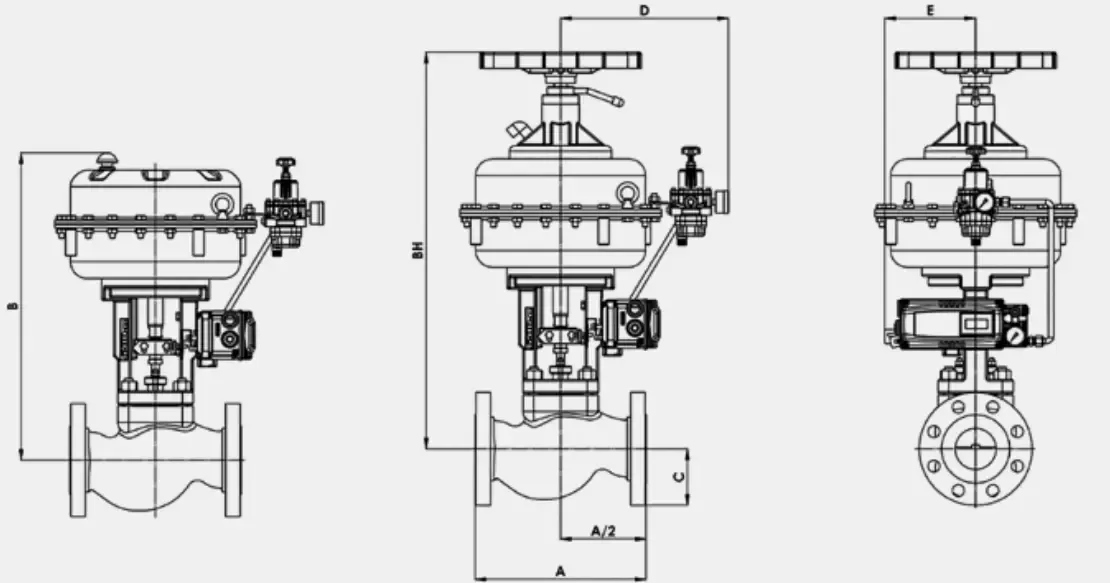

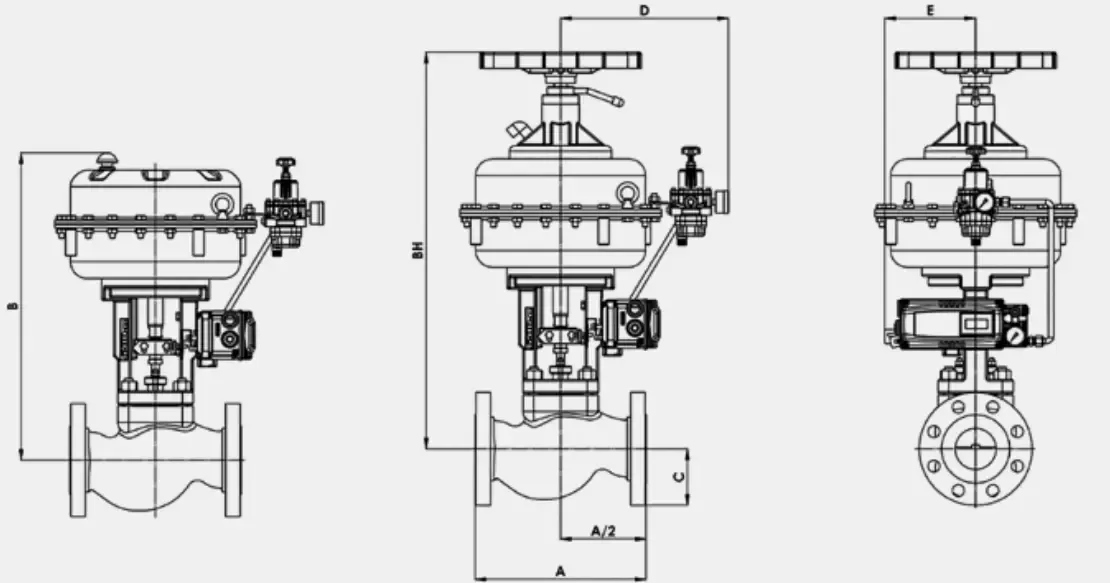

Control valves are designed to handle high-pressure drops while minimizing issues like erosion and noise. Features like the multi-spring actuator for precise control, proven trim design for noise reduction, and fail-safe modes ensure robustness and reliability. Screwed seat designs simplify maintenance and repairs.

Control valves offer numerous advantages, including:

Tight shutoff with ANSI IV to VI shutoff classes for leak-free performance.

Versatile actuation options such as pneumatic, electric, and hand-wheel actuation.

Ease of maintenance with top-entry design for quick access and simple trim changes.

Corrosion resistance through various materials that comply with NACE standards for corrosive fluid services.

Control valves are used in a wide range of applications, including:

Heater drains, condensate water systems, steam services, and spray water systems for efficient temperature and pressure regulation.

Level control, pressure regulation, and flow control in tanks, pipes, and other fluid handling systems.

Innovations like anti-cavitation trim, low-noise trim, and digital positioners offer enhanced performance in challenging applications. Smart valve technology allows for remote monitoring, predictive maintenance, and real-time diagnostics, further improving operational efficiency and reducing downtime.

Materials such as carbon steel, stainless steel, and exotic alloys like Hastelloy are used to ensure durability and resistance to corrosion and high temperatures. Valves comply with NACE MR0175/ISO 15156 for resistance to sulfide stress cracking and meet various industry standards, including ANSI, ASME, and API.

Proper installation and regular maintenance are essential for optimal performance. Key considerations include:

Correct sizing to prevent operational issues.

Proper alignment during installation to avoid premature wear.

Routine inspections and timely maintenance tasks such as component replacement and lubrication.

Control valves play a crucial role in industrial operations, ensuring efficient fluid control in demanding conditions. Their advanced design features, reliability, and ease of maintenance make them essential in industries like power generation, oil and gas, and manufacturing. As technology advances, control valves continue to evolve, supporting improved operational efficiency and sustainability.Know more about Google SEO Directory