Notifications

4 minutes, 52 seconds

-29 Views 0 Comments 0 Likes 0 Reviews

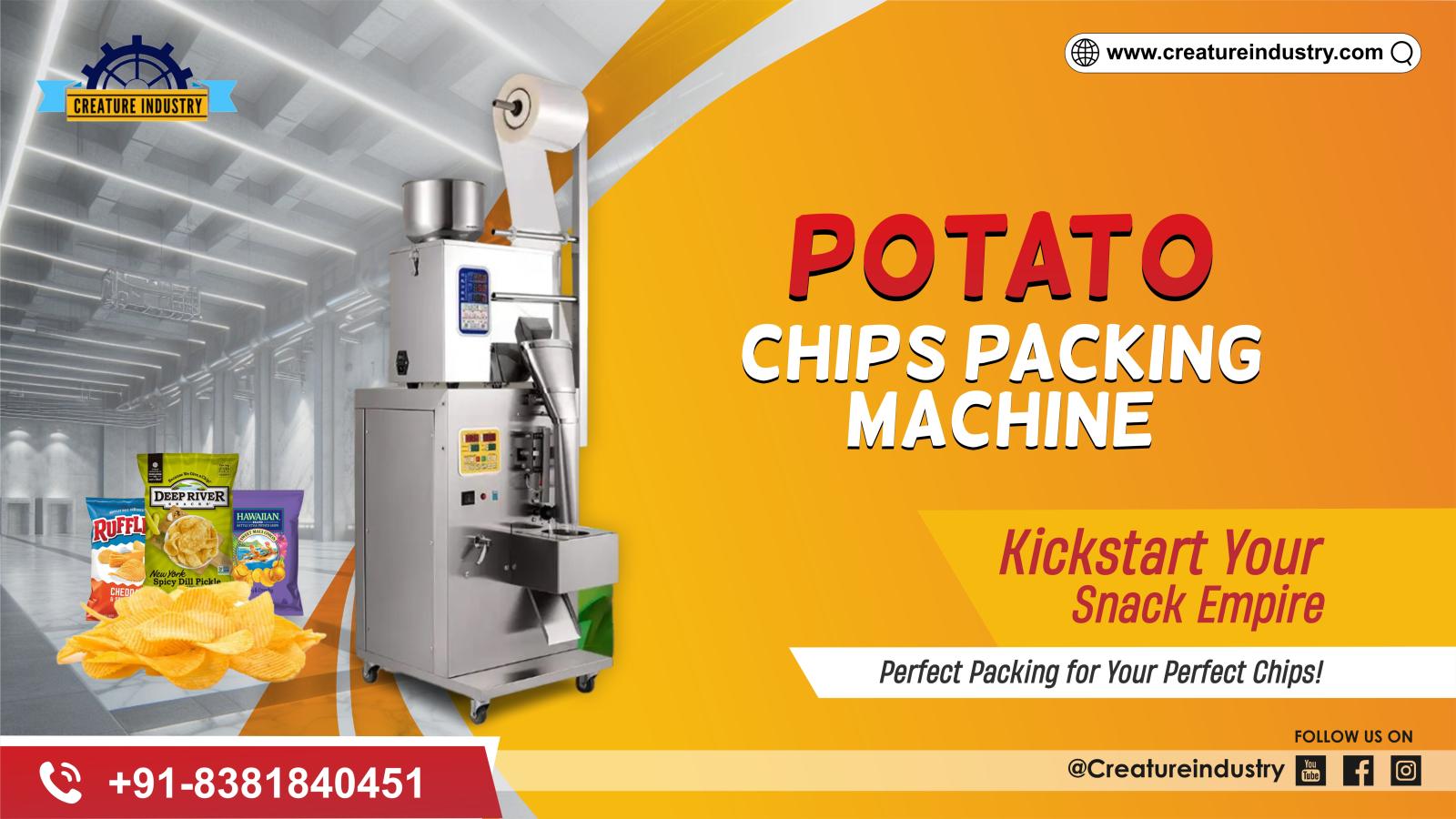

In the rapidly evolving world of food processing and packaging, the demand for highly efficient, precise, and reliable chips packing machines has surged. These machines are integral to maintaining the freshness, taste, and quality of chips while optimizing the packaging process.

A chips packing machine is designed to automate the process of weighing, filling, sealing, and packaging chips in various bag sizes and materials. These machines are crucial for snack manufacturers looking to enhance productivity, reduce labor costs, and maintain product consistency.

Feeding System: Ensures the smooth flow of chips into the packaging section without causing breakage.

Weighing System: Utilizes high-precision sensors to measure the exact quantity of chips for each packet.

Bag Forming Unit: Shapes the packaging material into bags suitable for chips.

Sealing Mechanism: Ensures airtight sealing to preserve freshness and extend shelf life.

Control Panel: Allows operators to set parameters for speed, bag size, and weight with ease.

These machines are widely used due to their versatility and compact design. They form bags from a flat roll of film, fill them with chips, and seal them efficiently.

Equipped with multiple weighing heads, these machines provide high-speed and accurate packing, ideal for large-scale production.

Designed for pre-formed pouches, these machines offer quick changeovers and are suitable for various snack types, including chips.

These machines handle different pouch styles and sizes with ease, making them perfect for flexible packaging solutions.

Enhanced Efficiency: Automates repetitive tasks, significantly reducing manual labor.

Improved Accuracy: Ensures consistent weight and packaging, minimizing product wastage.

Cost-Effective: Reduces operational costs through automation.

Extended Shelf Life: Airtight seals preserve freshness and prevent contamination.

Versatility: Capable of handling various packaging materials and bag sizes.

When selecting a chips packing machine, consider the following factors:

Production Capacity: Match the machine’s speed with your production requirements.

Type of Packaging Material: Ensure compatibility with the materials you plan to use.

Bag Size and Style: Choose a machine that can handle the desired bag dimensions and styles.

Budget: Balance between features and cost to find a machine that offers the best value.

Ease of Maintenance: Opt for machines with user-friendly designs and readily available spare parts.

Modern chips packing machines incorporate advanced technologies to boost efficiency:

Smart Sensors: For real-time monitoring and adjustments.

Touchscreen Interfaces: Simplify operation and parameter settings.

Energy-Efficient Designs: Reduce power consumption without compromising performance.

Modular Construction: Allows easy upgrades and customization.

Regular maintenance ensures the longevity and optimal performance of your chips packing machine:

Routine Cleaning: Prevents residue buildup that can affect machine operation.

Lubrication: Keeps moving parts functioning smoothly.

Inspection: Regular checks for wear and tear help in the early detection of issues.

Software Updates: Ensure the control system is up-to-date for improved functionality.

Inconsistent Sealing: Check for proper alignment and temperature settings.

Weight Variations: Calibrate the weighing system regularly.

Film Tracking Issues: Adjust tension and alignment of the film roll.

Machine Jams: Clear blockages and inspect for damaged components.

Investing in a high-quality chips packing machine is a strategic move for snack manufacturers aiming to enhance productivity, ensure product consistency, and meet market demands. With the right machine, you can achieve efficient, cost-effective, and reliable packaging solutions.